With the market launch of the first plug-in hybrid versions of the BMW core brand models production of BMW eDrive components in Dingolfing is scaling up. Ever since the launch of the first BMW i production models, the Dingolfing plant has produced high-voltage batteries and other powertrain and chassis components for these vehicles. Prior to that, the plant already supplied high-voltage batteries for the BMW Active E, BMW 3 Series ActiveHybrid, BMW 5 Series ActiveHybrid and BMW 7 Series ActiveHybrid.

Over the past years, the BMW Group has invested more than €100 million in electric drive technology in Dingolfing, to strengthen the plant’s competitiveness. Although the production processes for electric motors and high-voltage batteries are highly automated, the plant is taking on increasing numbers of highly qualified employees. The number of people employed in production of components for plug-in hybrid vehicles will increase from around 100 at the present time to more than 200 in the medium term.

Technology transfer from BMW i generates innovations in production and equips it for the future. The transfer of technology and know-how from the development of BMW i models also extends to the production side. The experience acquired by BMW i not only flows into improving key features of the BMW eDrive components themselves, it also makes for more flexible and quality-oriented production processes at the Dingolfing plant.

Electric drive components that play a key role in the driving experience are developed in-house. In addition to electric motors and the high-voltage batteries, this also includes the power electronics and the vehicle electrical system – which provide the basis for intelligent energy management. The decision to develop and produce eDrive technology within the company means the BMW Group has acquired a level of systems expertise that is unique among its competitors. Extensive know-how about all the individual system components is paired with an in-depth understanding of electric drive technology as an overall system. All this helps to strengthen the BMW Group in its quest to be the industry leader in the EV segment.

Modular design system offers the twin advantages of standardization and flexibility. The parallel relationship between the product portfolio and the production process can be seen in the configuration of the new manufacturing facilities at the BMW Group’s plant in Dingolfing. A total area of approximately 6,000 square meters in the new production hall acts as the global production network’s main manufacturing site for eDrive components.

Approximately 1,500 square meters of space is devoted to the production of electric motors and battery modules, while a 1,000-square-metre area is used for the assembly of the high-voltage batteries. In all these areas, the manufacturing facilities are configured to allow rapid expansion of production capacities, which can even be doubled in size with no negative impact on the efficiency of the production process. Also, a number of existing vacant spaces on the site could potentially be used to extend the overall production capacity for electric drive systems even further.

Similar flexibility can be seen in the eDrive product portfolio itself. The BMW Group has developed a modular design system whereby electric motors and high-voltage batteries of varying size, performance and type can be developed on the basis of shared, standardized design principles and common basic characteristics. With this combination of standardization and flexibility, the Group is equipped to cover the requirements of all of its current and future all-electric and plug-in hybrid models.

The electric motors play a key part in this. The motors used in the BMW i and BMW iPerformance models feature a high power-to-size and power-to-weight ratio and offer linear power delivery extending right up into the high rpm range, along with exceptional efficiency. These characteristics are the product of a special design principle, the incorporation of BMW i know-how into a wide range of detailed features, and innovative production processes.

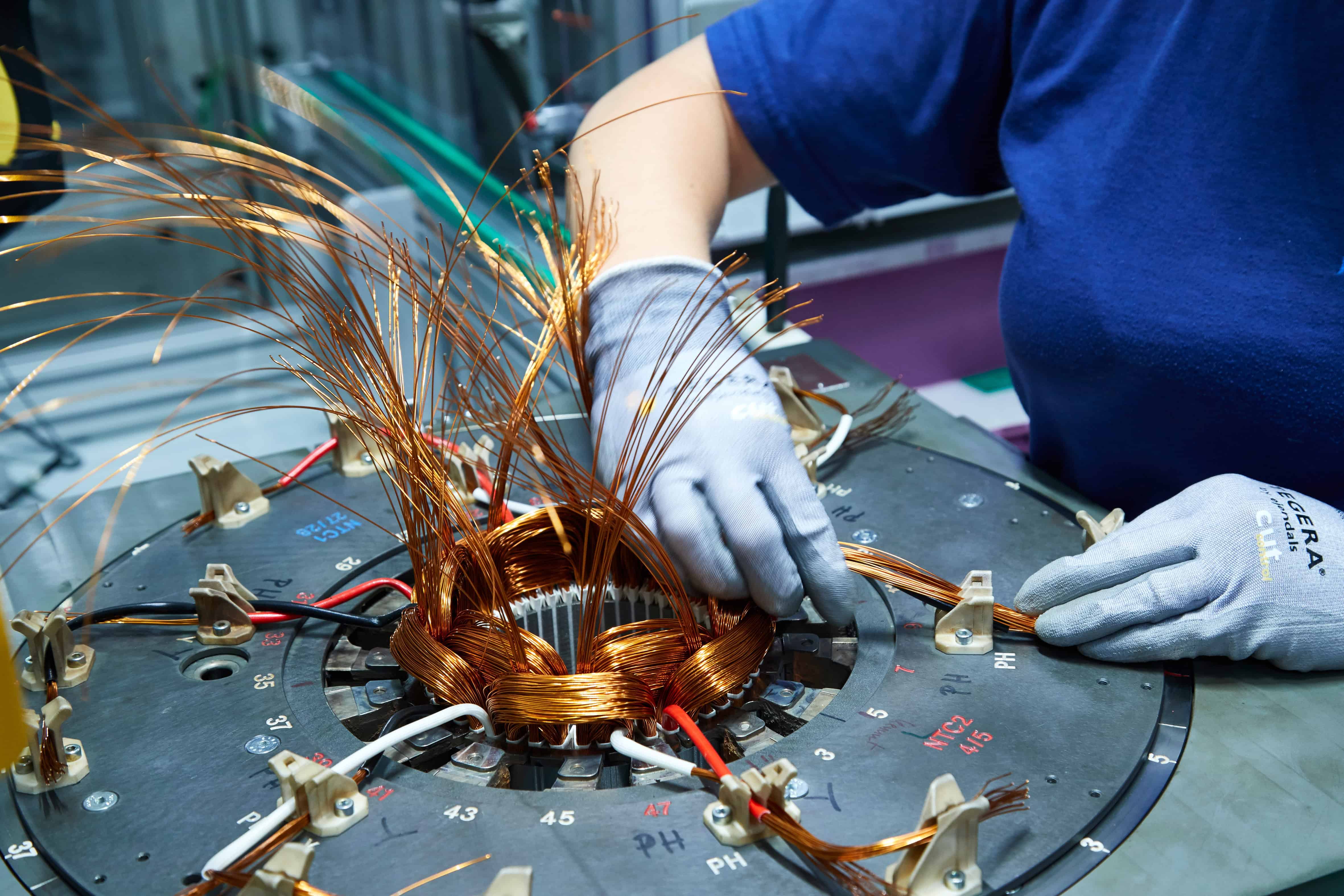

The stator and rotor, both produced at the BMW Group’s Dingolfing plant, are then attached to the casing of the motor. The assembly line is highly flexible, and individual employees are trained to be able to perform a range of different operations. The U-shaped arrangement of the workstations ensures that this flexibility is combined with high efficiency. At all stations the components are delivered to the operator in an ergonomic manner. At the same time the work stations are adjustable for height and tilt to suit individual ergonomic needs. Most operations can be performed either from a sitting or a standing position. This special way of working contributes to the high production quality of the eDrive components that leave the Dingolfing plant.

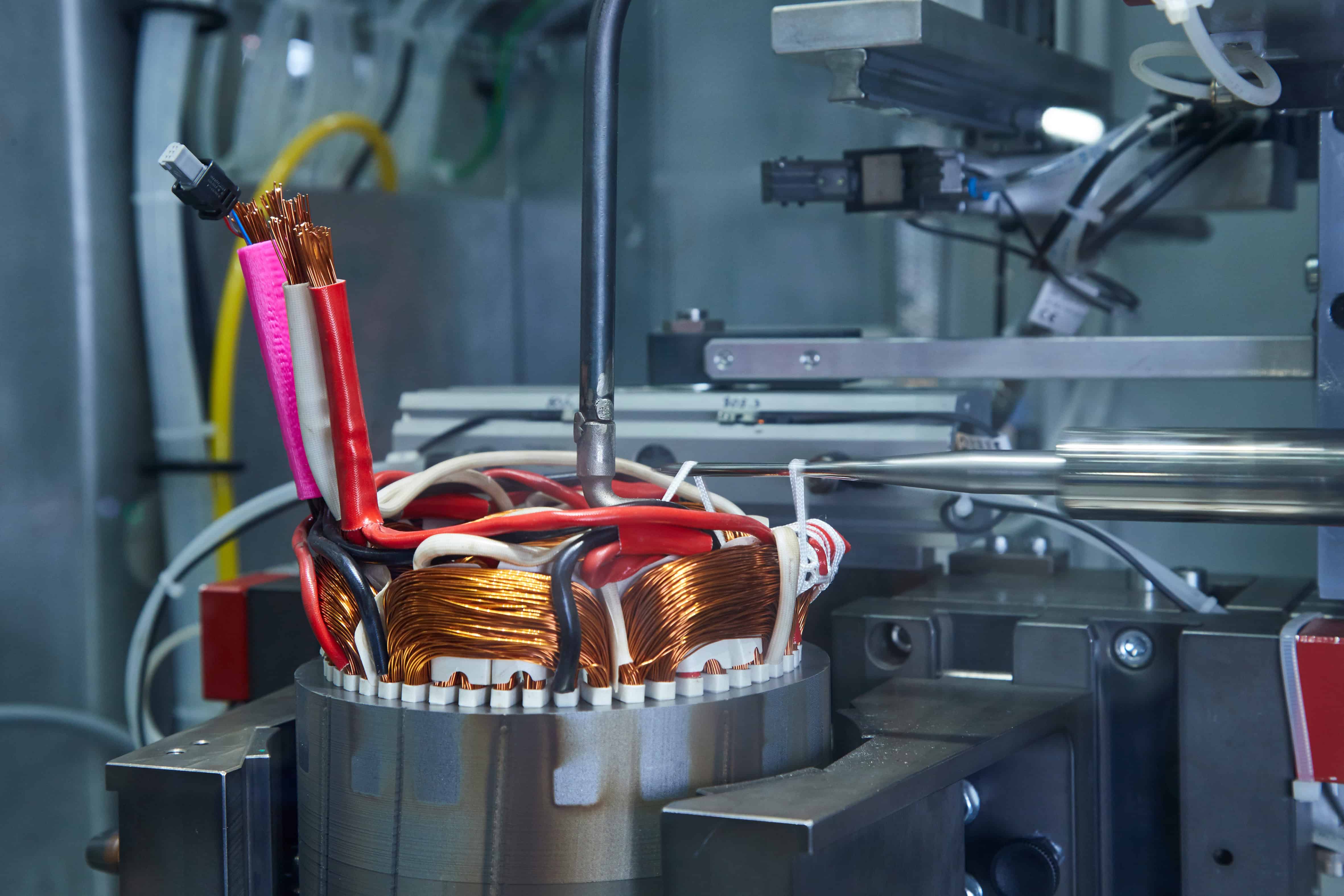

The high specific output and sporty characteristics of eDrive motors are a result of the extensive optimization of the permanently excited synchronous electric motor technology on which these motors are based. For example the stator consists of up to two kilometers (1 ¼ miles) of copper wiring, which is specially wound for extra compact dimensions. The stator production process comprises the packaging and insulating of the individual sheet metal sections, and drawing in and forming the coils.

The sheet metal sections are joined by laser welding. Rotor assembly also follows a special process. After the magnets have been inserted and caulked in the rotor structure, which is made up of numerous sheet metal sections, the cooled rotor shaft is shrink-fitted into the heated component. Only then is the rotor magnetized, which considerably simplifies the overall assembly process. During final assembly of the motor, the stator is first of all shrink-fitted into the motor casing, which has previously been induction-heated to a temperature of around 150 degrees Celsius. Then the rotor is inserted. After all other parts have been fitted, and a function test has been carried out, the fully assembled electric motor can be flange-mounted to the transmission.

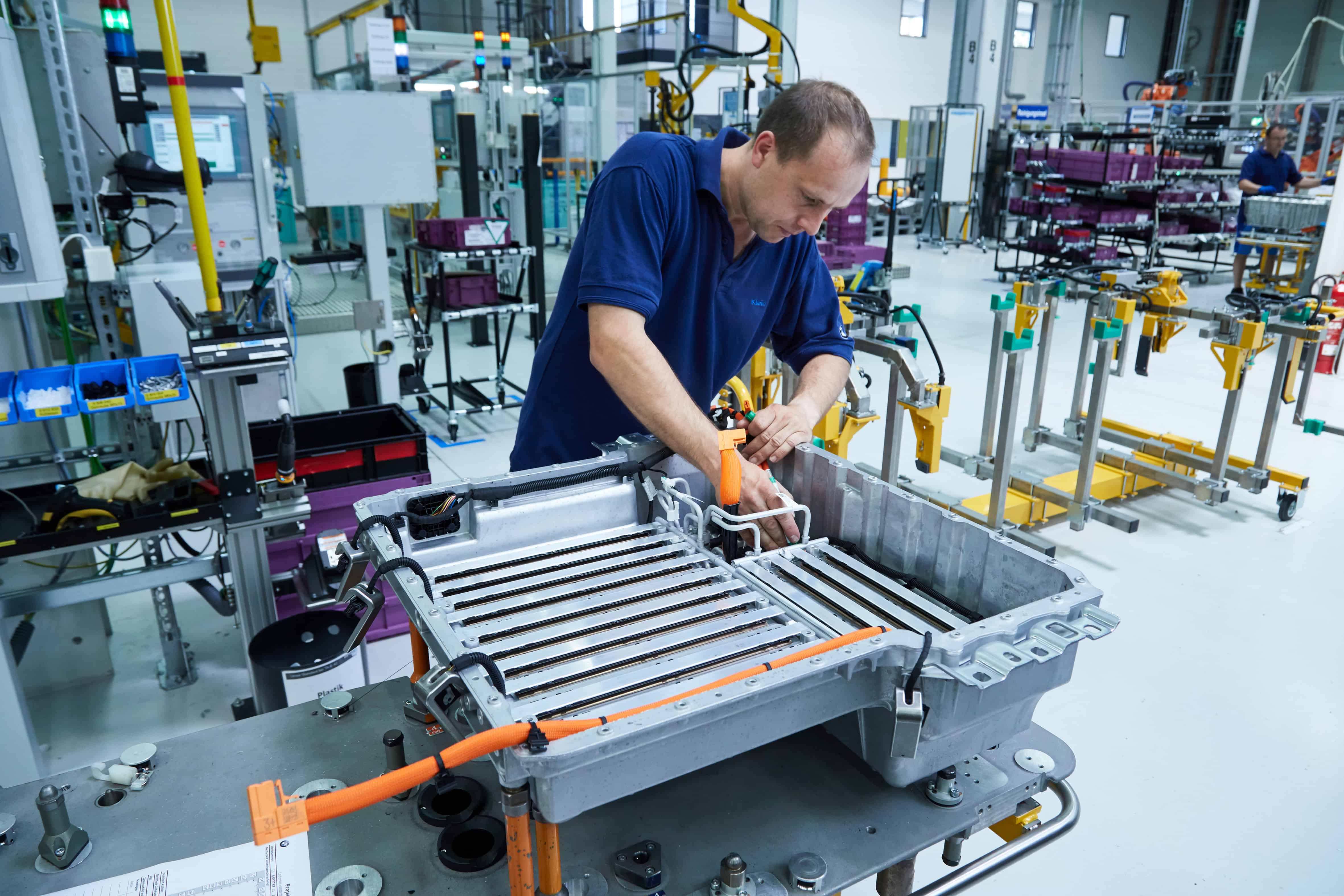

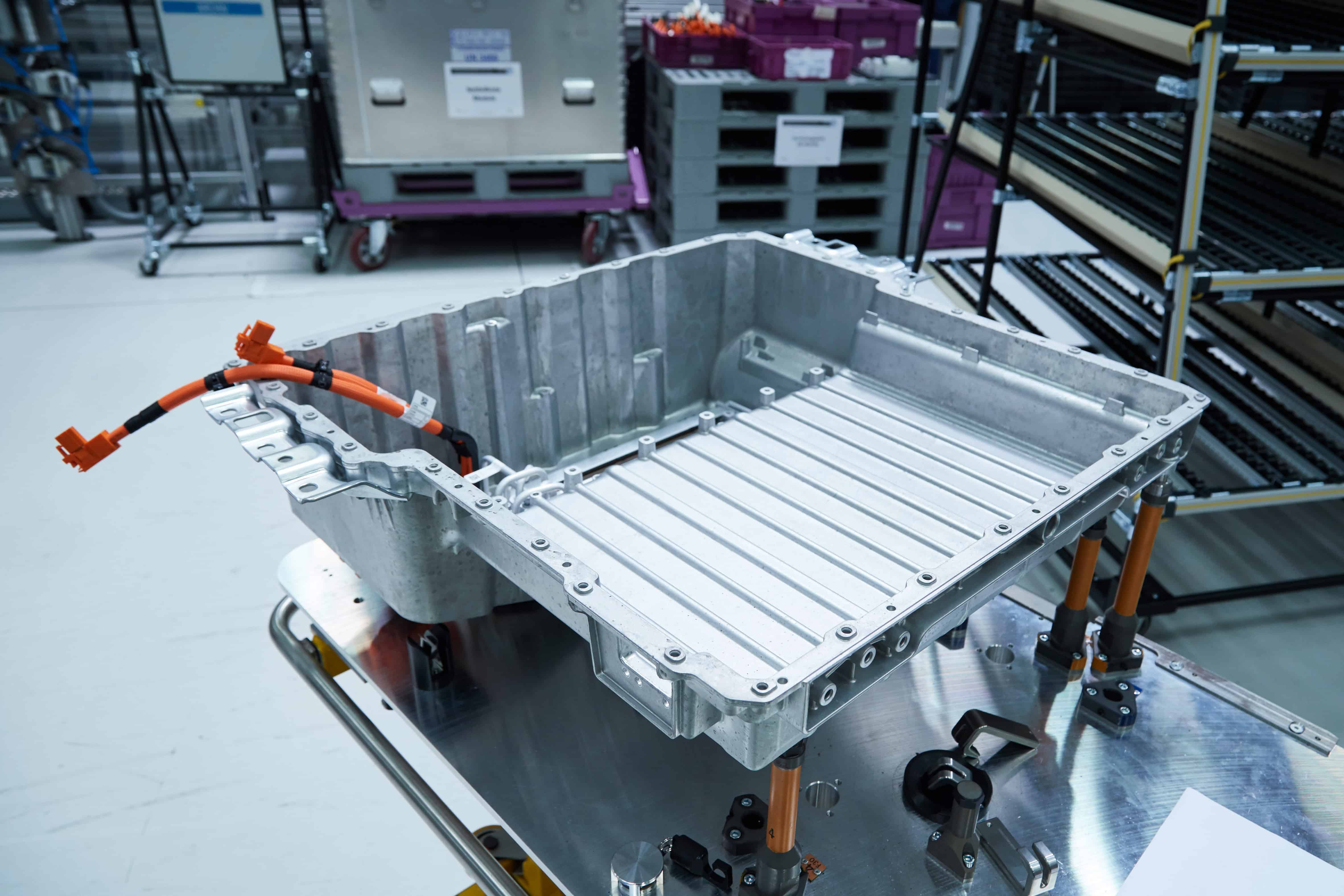

Production of the high-voltage battery packs for BMW i and BMW iPerformance models at the Dingolfing plant happens in two stages. The first, highly automated stage involves packaging the externally supplied lithium-ion cells into modules. These modules, each comprising 16 cells, are then mounted, together with the connectors, controllers and cooling systems, in an aluminum housing.

The battery packs are in each case configured to meet the requirements of the model in which they are installed, and may comprise either five or six modules. The modular design principle allows high-voltage battery packs with common basic characteristics and quality standards to be custom-configured to the size and geometric requirements of the specific model. Every model can therefore be fitted with a battery that is optimally adapted to the available installation space and the intended positioning of the battery in the vehicle.

Following an initial inspection on arrival at the Dingolfing plant, the externally supplied battery cells, which are built to the BMW Group’s precise specifications, are readied for the largely automated module assembly process. Robots then apply a layer of bonding agent, package the cells into groups, pressure-weld the module frame to the grouped cells, fit the thermal interfaces and laser-weld the cell contacts.

The finished modules can then be assembled into a complete battery pack tailored to the requirements of the specific model. The BMW Group’s Dingolfing plant currently produces three different types of high-voltage battery pack, using what is known as a cellular manufacturing process. Cellular manufacturing offers exceptionally high levels of flexibility, while also ensuring efficiency and quality. This means that for batteries too, manufacturing capacity can be adjusted at any time to meet changing requirements, while new versions can always be easily integrated into the production process.

Depending on the version, the battery pack comprises five or six modules, which are installed in an aluminum casing equipped with pre-installed cooling systems and connectors. The modules are automatically bolted in place and linked up using electrical connectors. This installation technique means that in the event of a fault it is possible to simply swap individual modules rather than having to replace the entire battery. The servicing workload is further reduced by the internal layout of the battery, which allows the insulated modules to be taken out without risk after opening the casing. Last but not least, the swapping of battery modules only requires minimal dismantling of the cooling system.

The coolant circuit of the vehicle’s air conditioning system is also used to cool the battery. Its gaseous coolant provides direct cooling of the cells. This approach ensures highly efficient temperature control, since the heat transfer from the evaporation process is direct and therefore much more efficient than if an additional medium were used. This allows a particularly compact cooling system to be used. At the same time, there is no risk of liquid being released in the event of a collision.