The future of driving and the automotive industry is increasingly entwined with technology. From self-parking tech to Level 3 (and beyond) driving autonomy, BMW is doing everything possible to keep up. In fact, they’ve built an entire complex dedicated to it. Made up of dozens of roads, a self-contained highway, and even its own mock city, the new facility offers cutting-edge advantages while testing vehicles. Introducing: the BMW Group Future Mobility Development Center (FMDC) in Sokolov, Czech Republic.

Purpose-Built: a Glimpse of the BMW FMDC in Sokolov

The Sokolov facility was built to develop, test, and prove autonomous concepts. Built from the ground-up beginning in 2014 to deliver a consistent environment for testing, it covers 600 hectares that will eventually comprise six test tracks, nearly 11,000 square meters of office buildings and workshops, and much more. Initially, this was a brown field with a nearby coal mine spanning over 2400 hectares. BMW says that this location was a valley with a river crossing through which was eventually rerouted. The valley was then filled with earth from the coal mine.

Certainly, BMW faces certain challenges due to the relatively young and dynamic nature of the earth. The constant movements of the earth necessitated a thoughtful approach to stabilize a 150-meter-long building. To achieve this, BMW had to employ a remarkable solution involving the installation of 1,200 pillars, each 10 meters deep and 900 mm wide.

BMW has invested over €300 million into making Sokolov the perfect proving ground for new driver assistance systems. Eventually, Sokolov will feature 100 kilometers (62 miles) of test road. Among them is a 6 km (3.7 mi) stretch of track dedicated to simulating highway conditions. This will be where Level 3 autonomy and beyond will be tested out. The track offers replaceable and easily repaired objects that resemble obstacles vehicles might encounter on the road. Other notable tracks include “bad roads built well,” which simulates a poorly maintained street, and a stretch of highways with signage from all over the world stretching 4 km (2.5 mi). The former helps reflect varying street conditions. The latter is to ensure vehicles can read road signs no matter what region of the world they’re in.

Like a Good Neighbor…

BMW plans to continue operations at Sokolov for “many decades to come.” With that promise comes a need to be a good neighbor. In the circular spirit of new BMW initiatives, BMW actively participates in the region in many ways. They’ve partnered with Kids Technical University, have arranged annual donation programs, and have a focus on community-improving projects like education, sustainability, and road safety.

What Does It Looks Like

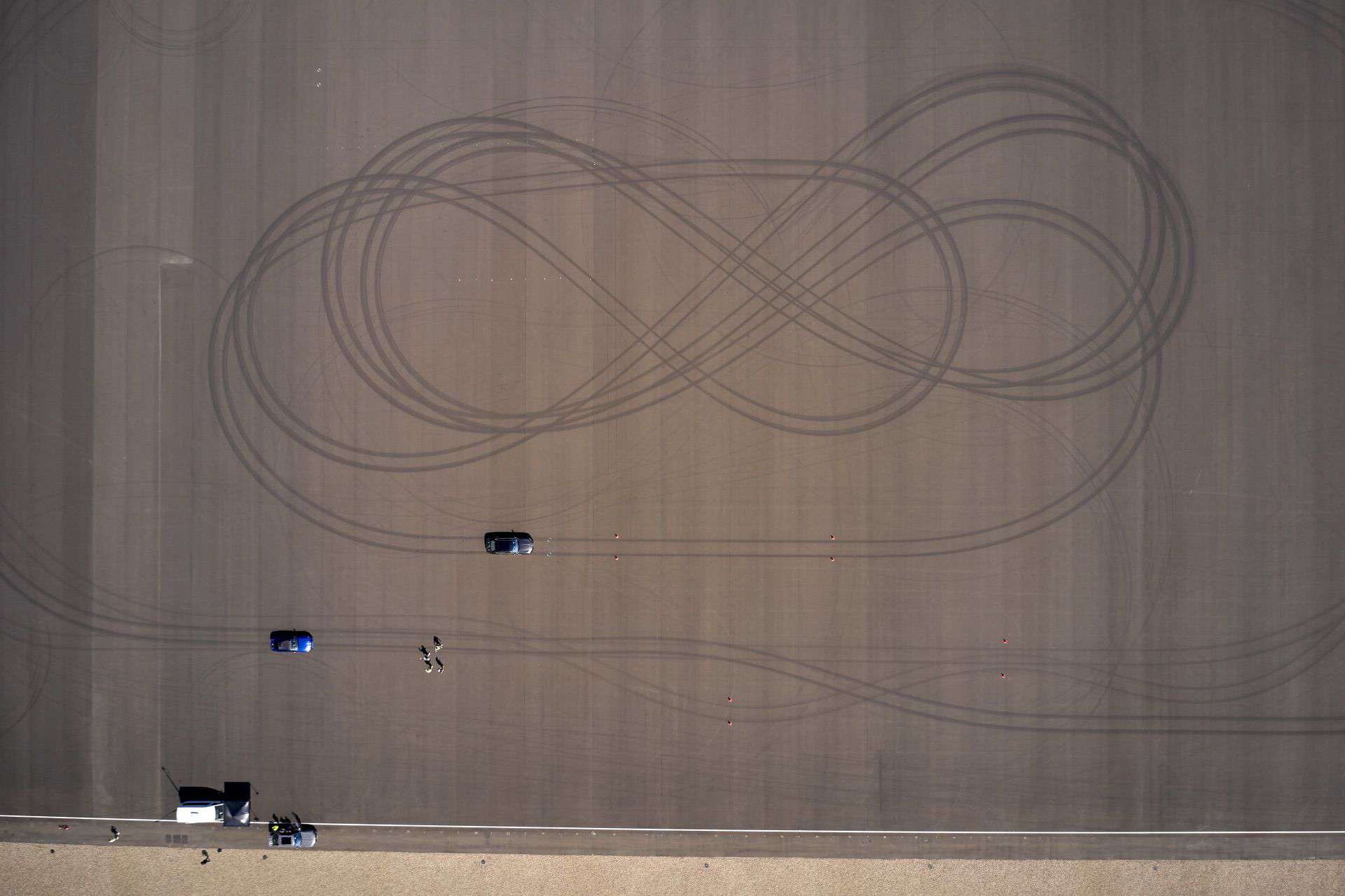

In June, we were given the opportunity to visit the Sokolov facility, where we witnessed the extraordinary process of constructing an entire city from scratch. The facility itself is modern, resembling a fully functional but unoccupied city. Complete with highway and interstate roads, bridges, tunnels, and extensive tracks, the Sokolov facility provides an ideal testing ground for various BMW teams to evaluate and refine a diverse range of products.

In this simulated city environment, even though it is devoid of actual residents, speed limits on the roads are enforced. As you navigate from one location to another, it’s essential to adhere to these rules. Every BMW Safety Car is equipped with a smartphone that monitors your speed and provides warnings if you happen to exceed the designated limits. This ensures safety and compliance within the facility while allowing for a realistic testing experience.

The Most Modern Test Site Ever: the Sokolov BMW Proving Grounds

So, nearly a decade of work, over 2 million cubic meters of Earth moved, and 1,200 ground-stabilizing pillars later, the Sokolov FMDC is finally ready to test autonomous driving features. It’s clear that the Sokolov facility will play an integral part in developing the driver assistance systems of the future. BMW will eventually employ 250 people in Sokolov, most of them contracted partners. There will also be 100 BMW employees responsible for testing procedures.