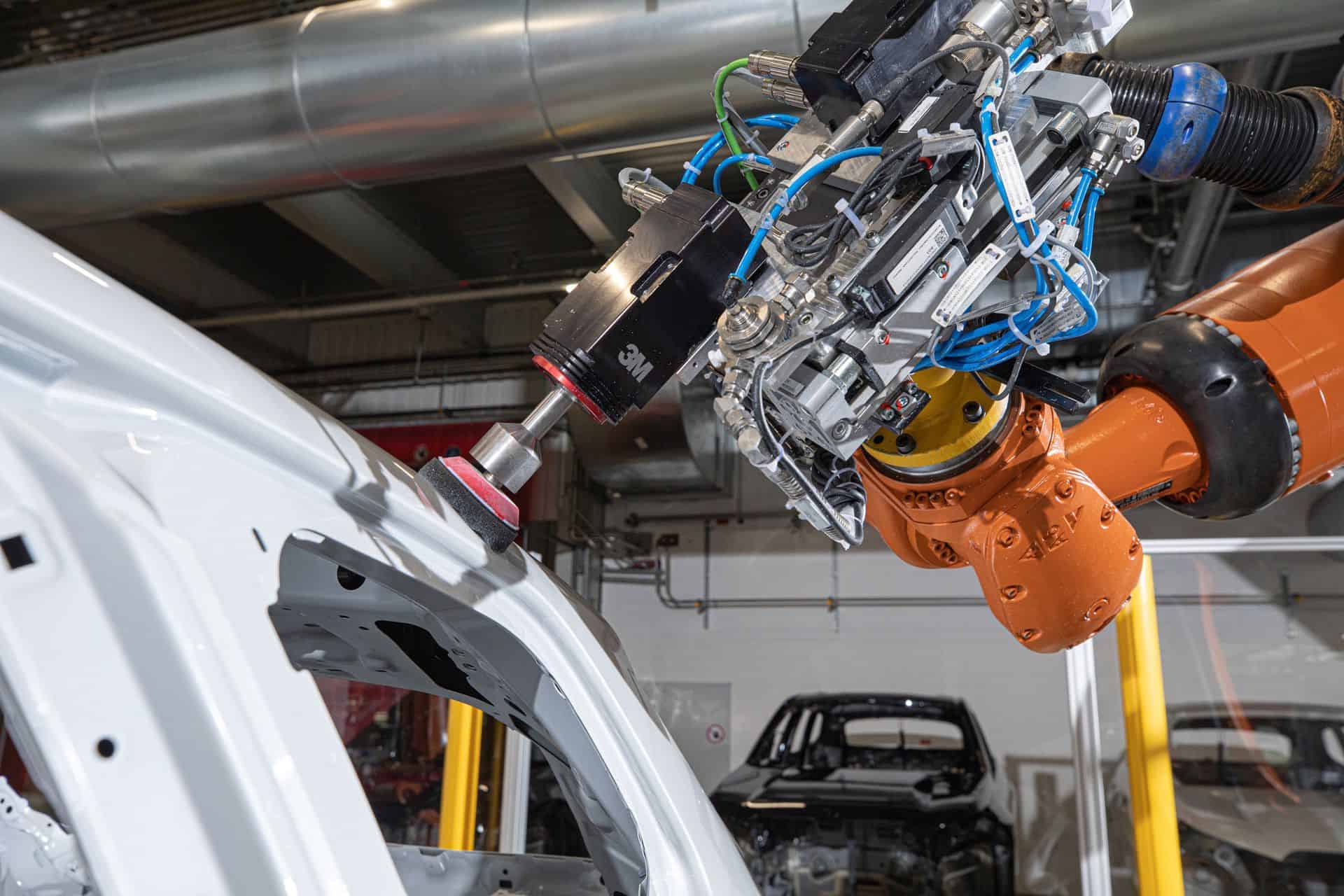

The BMW Group Plant in Regensburg is introducing a cutting-edge process for inspecting, processing, and marking painted vehicle surfaces. The German plant has implemented an end-to-end digitalized and automated process that is the first of its kind globally. Using AI-controlled robots, each vehicle is processed individually to meet stringent quality standards, resulting in a consistently high-quality vehicle surface. The data collected is stored in the cloud, allowing for optimal analysis of causalities.

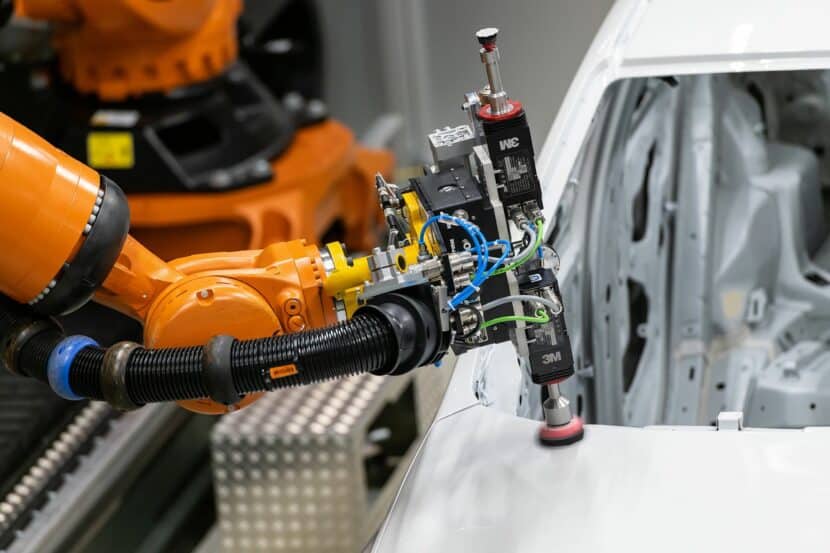

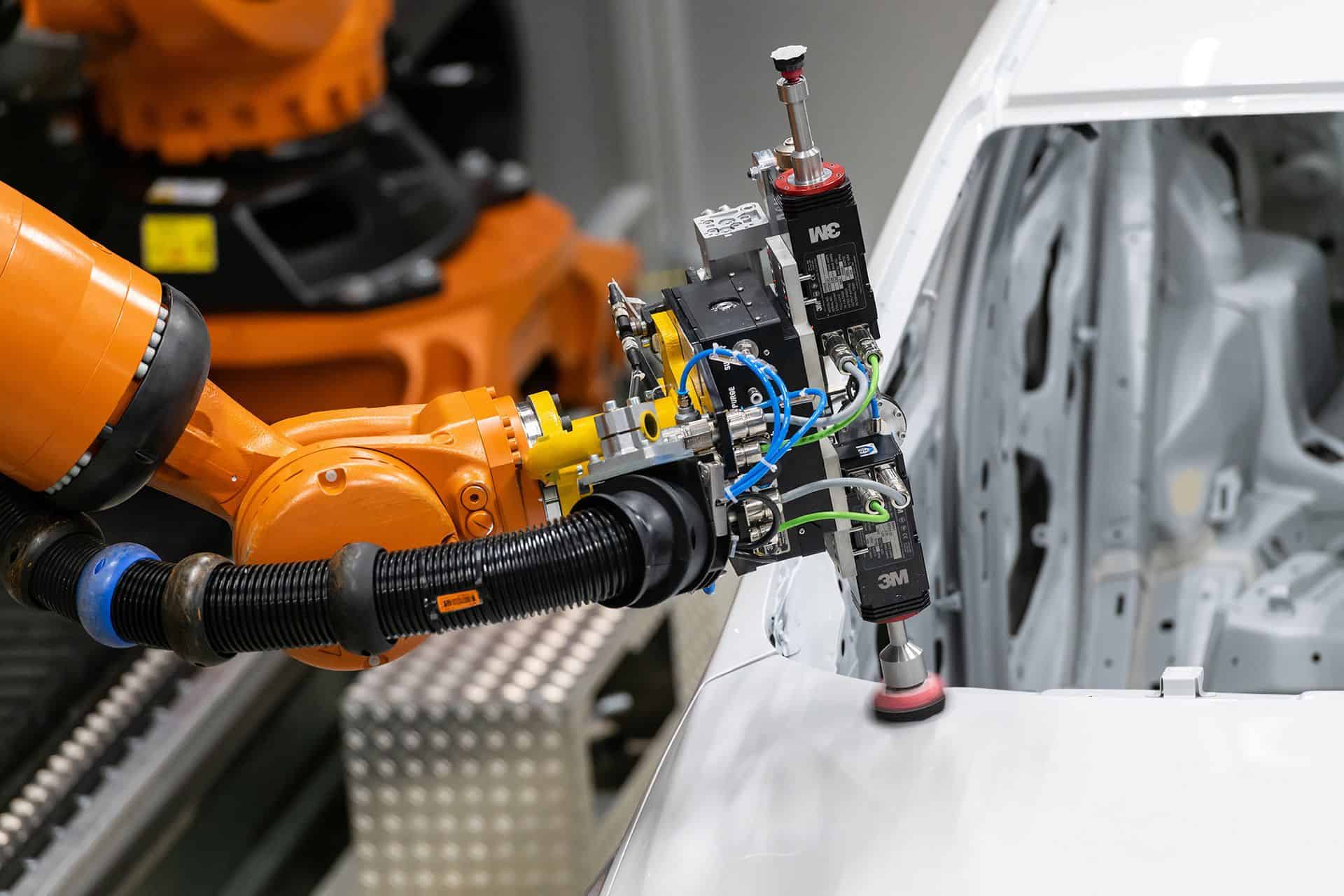

Unlike traditional methods, the robots work on the surface of each vehicle as needed. The process involves sanding, polishing, and changing attachments and sandpapers to ensure that any specks or bumps are addressed. This tailored approach ensures that every vehicle receives unique processing, resulting in a high-quality finish. With up to 1,000 vehicles processed each day, this innovative process ensures stable operations and shorter lead times.

AI-based Processes

This process has been in use since March 2022, and BMW Group Plant in Regensburg is the first automotive plant to implement such an AI-based process. The process starts with Automated Surface Inspection, which identifies and records the features that require processing after the topcoat has been applied. This step ensures the smooth operation of the process and ensures that every vehicle receives the same high-quality finish.

The Automated Surface Inspection system uses deflectometry to identify any deviations in the reflective paintwork, which is detected through the change in black and white striped patterns projected onto the surface. The data is then saved to a connected computer system, which creates a digital 3D image of the surface and classifies it based on objective criteria. This ensures that all vehicle surfaces are inspected for customer quality assurance purposes and treated as needed.

While robots are used in the process, they have limitations and cannot process certain areas such as the edges of the body or the final millimeters next to the door and other joints. Therefore, trained employees add the finishing touches and conduct the final inspection of the body. The recorded data is used to support their work, with a laser projector marking relevant areas of the body surface to ensure nothing is overlooked.

BMW Group Plant Regensburg is the first to use this three-stage automated process in standard production, with plans to roll it out to other plants in the future. [Source: BMW]