BMW recently announced that it plans to phase out internal combustion engines from the MINI line-up in the future. The British brand will be selling electric-only models starting from 2030 and that’s all done in the hope of helping our environment. That’s only part of the plan though. Making electric cars isn’t enough, you also have to make sure the production process is as clean as possible as well as all the logistics associated with it.

To that end, MINI announced today that it will be using LNG trucks moving forward, in a bold move to cut CO2 emissions on the logistics side of things. LNG, or liquid natural gas, is an alternative to diesel that will bring an average CO2 and NOX emissions cut of 20 percent, compared to diesel alternatives. Furthermore, that drop is expected to reach 90 percent once the trucks switch to bio-LNG.

At the moment, MINI is using 18 trucks from its partner in this endeavor, Imperial. The trucks are transporting parts and components from various suppliers across 15 different routes in the UK at the moment. “With environmental benefits, lower emissions and quieter engines, these LNG-powered lorries will deliver components from across the UK to the heart and home of MINI in Oxford,” said Thomas Frank, Director of Logistics, MINI Plant Oxford.

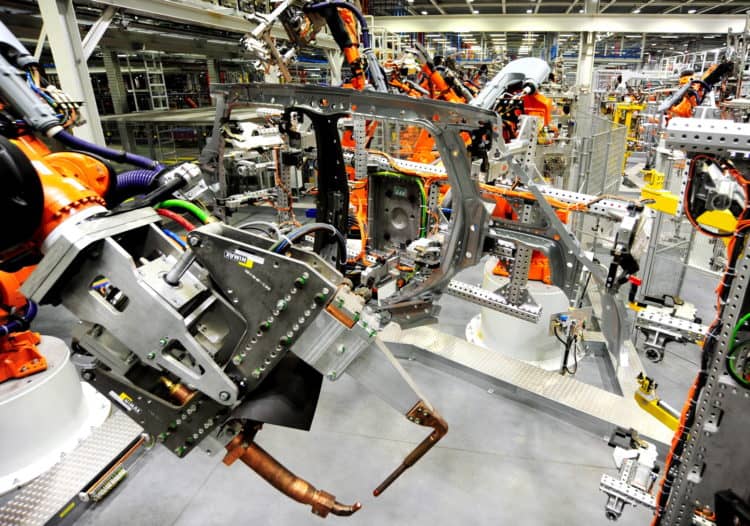

MINI Plant Oxford has already adapted to a 360-degree sustainability strategy involving heat regeneration, environmentally friendly production, the harvesting of rainwater and one of Britain’s largest solar energy facilities. The next step is to increase sustainability in all areas of its supply chain and logistics operations. Transport logistics has a key role to play in achieving the BMW Group’s supply chain sustainability target, by reducing CO² emissions per vehicle by 20 per cent by 2030 compare to 2019. CO²-minimizing ‘Green Logistics’ concepts are also being developed as MINI is transforming into an all-electric brand.