BMW announced today its commitment of offering a sustainable hydrogen fuel cell technology in series production vehicles in the near future. According to BMW, the Bavarians are carefully and constructively building a multi-pillar powertrain and mobility strategy. When the market is ready, the hydrogen fuel cell technology could become the fourth pillar of the strategic approach in the long-term. BMW Group is confident that conventional engines will continue to co-exist with electric, plug-in hybrid and, potentially, hydrogen fuel cell alternatives for a long time.

Diversity is the key, as the automotive giant affirms. The road to free-emission mobility is taken on systematically and gradually, by carefully considering the differing market and client requirements as part of the company’s already established “Power of Choice” strategy.

Klaus Fröhlich, Member of the Board of Management of BMW AG, Research and Development, commented: “We are convinced that various alternative powertrain systems will exist alongside one another in future, as there is no single solution that addresses the full spectrum of customers’ mobility requirements worldwide. The hydrogen fuel cell technology could quite feasibly become the fourth pillar of our powertrain portfolio in the long term. The upper-end models in our extremely popular X family would make particularly suitable candidates here.”

With respect to the development of sustainable hydrogen fuel cell technology, efforts have been focusing on this direction already since 2013, when BMW partnered with Toyota Motor Corporation.

Future prospect for hydrogen fuel cell technology

BMW Group sees an adequate potential of the hydrogen fuel cell technology in the long term, but until market conditions are favorable, it will take some time before the first BMW FCEV (fuel cell electric vehicle) will be serially produced.

The hydrogen fuel cell technology depends firstly on having a sufficient amount of hydrogen produced using green energy sources and at competitive prices. Furthermore, the needed refueling infrastructure is currently lacking worldwide.

BMW also says is committed to pushing forward the creation of a Europe-wide network of hydrogen fuel stations with reaffirmed commitment to the further development and refinement of fuel cell technology.

Hydrogen fuel cell technology will become a viable and consistent alternative when the requisite infrastructure is put in place and when hydrogen refueling will be priced comparably with current gas/diesel refueling charges. Moreso, BMW sees primary application of the new technology in sectors where direct, full electrification is not possible, such as heavy-duty transport.

Cooperation with Toyota Motor Corporation continues

In 2013, BMW and Toyota embarked on a successful collaboration aimed primarily at the further development and industrialization of the hydrogen fuel cell technology and the production of scalable parts and modular components to be used in the hydrogen fuel cell vehicles.

The two companies are also founding parents of the Hydrogen Council, established in 2017, with 80 members having already joined the council since its foundation. The members are leading companies from the energy, transport and industrial sectors.

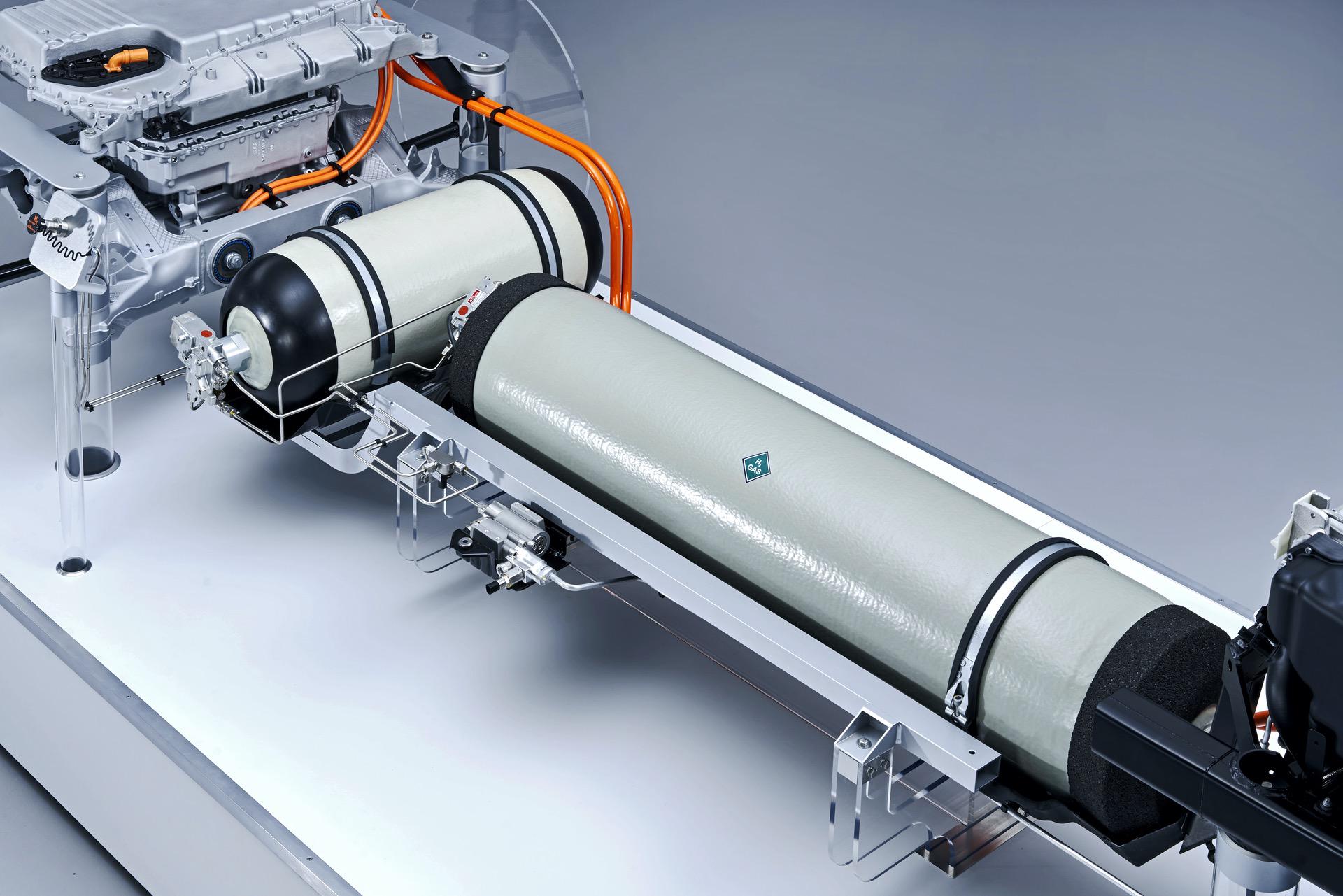

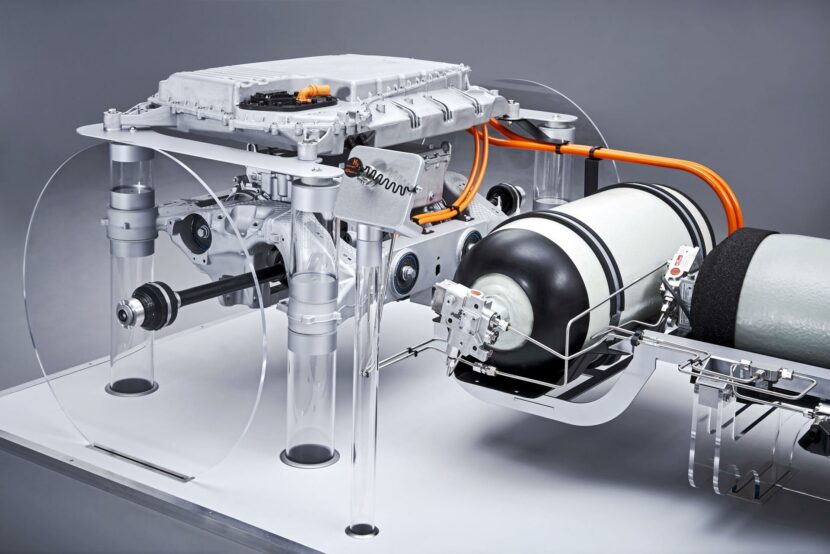

The hydrogen fuel cell powertrain together with the fuel cell units and modular components developed as part of the BMW-Toyota cooperation will be deployed in the BMW i Hydrogen NEXT beginning with 2022.

BMW Group involvement in the BRYSON research project

To be viable, the hydrogen fuel cell technology must be safe in the first instance. Developing a secure and space-optimal way of storing the liquid hydrogen in a car is a crucial step to make the technology fully compliant with safety standards.

As a consequence, BMW Group is part of the BRYSON research project aiming to develop pioneering high-pressure hydrogen storage tanks which are, as well, space-efficient and can be easily integrated into the future universal vehicle architectures.

Thus, BMW Group collaborates with the Munich University of Applied Sciences, Leichtbauzentrum Sachsen GmbH, the Technical University of Dresden and WELA Handelsgesellschaft mbH for this daring challenge. The ultimate purpose is to create a flat design for the storage tanks.

The BRYSON project is sustained through direct funding from the German Federal Ministry for Economic Affairs and Energy and is set to run for 3.5 years. In the end, it is estimated that BRYSON will help lower the cost of manufacturing hydrogen tanks for fuel cell vehicles, enabling them to compete effectively with battery electric vehicles (BEV).