BMW has faced quite a lot of criticism over its production of battery electric vehicles, or lack thereof to be more accurate. However, it seems as if the brand has been working in the background on EVs, developing its fifth-generation electric drive unit which we’ve seen in the Power BEV concept. It’s also been working on battery production, which has now been doubled at the BMW Spartanburg plant.

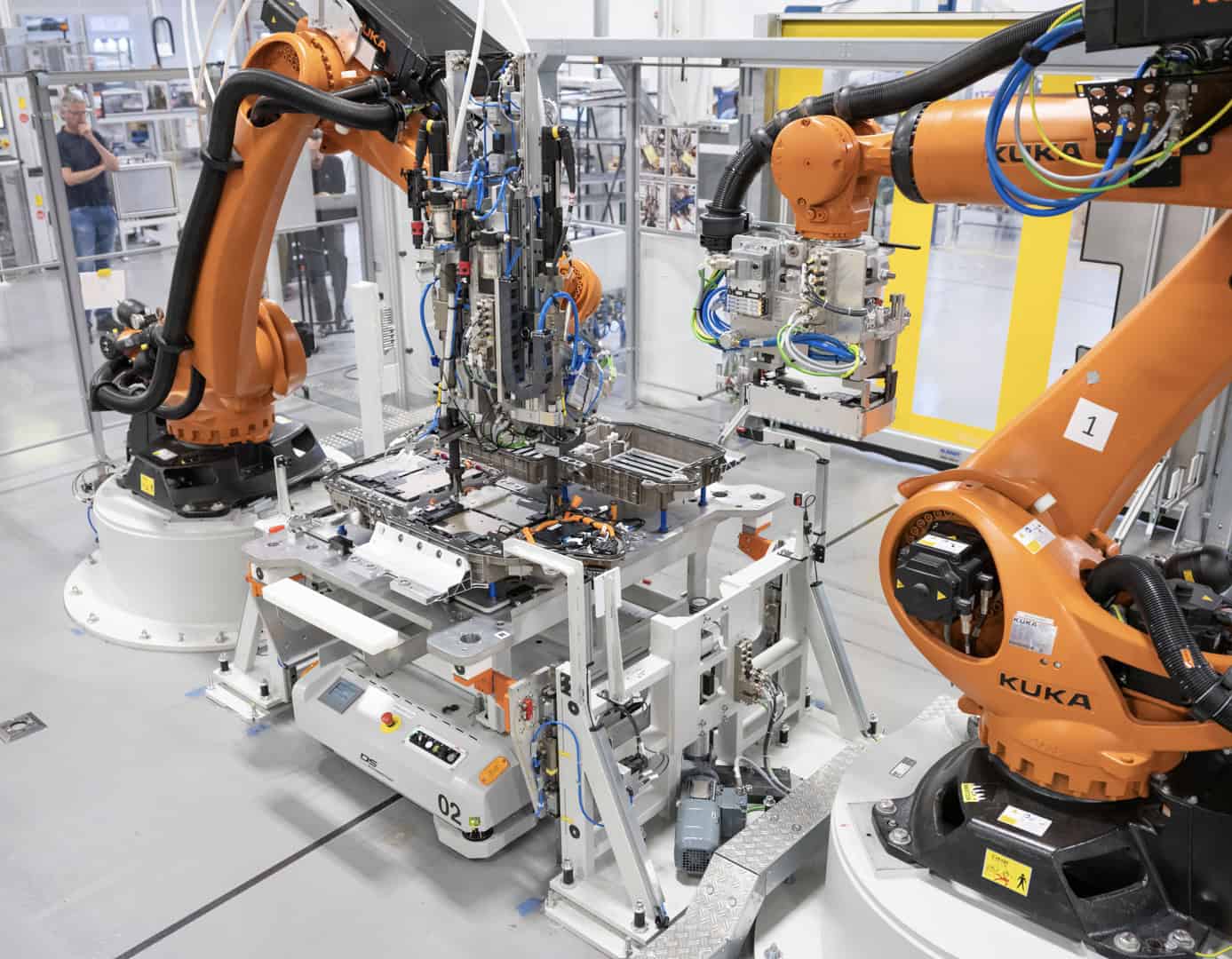

“We have invested around ten million US dollars in a new battery assembly line and expanded the area to more than 8,000 square metres. This means we could double the number of batteries produced if needed to meet market demand,” explains Michael Nikolaides, Senior Vice President Engines and Electrified Drivetrains, BMW Group.

Not only is it going to double its production capacity but it’s now developing different types of its fourth-generation batteries, which are based on new technologies. In the past four years, the BMW Spartanburg plant has developed over 45,000 batteries. That’s not a huge number but it is going to grow and the capacity for production is now doubled.

“We have produced batteries on site at Plant Spartanburg since 2015 – making the BMW Group a pioneer for electromobility in the US,” says Knudt Flor, President and CEO, BMW Manufacturing, Co., LLC.

These new batteries, will be used in upcoming plug-in hybrid models, such as the BMW X5 and X3. Which is largely why they’re being built at the BMW Spartanburg plant, which is where the X5 and X3 are built.

“The BMW X5 and BMW X3 are currently among the top-selling BMW models in the US. We expect their plug-in hybrid variants to be just as popular with customers,” adds Flor. Plug-in hybrid models will be important to the brand, as they sort of introduce customers to electrification without them having to make the switch fully.

BMW might not be the foremost maker of electric vehicles but it’s certainly ramping up production of both batteries, electric vehicles and the requisite technologies.