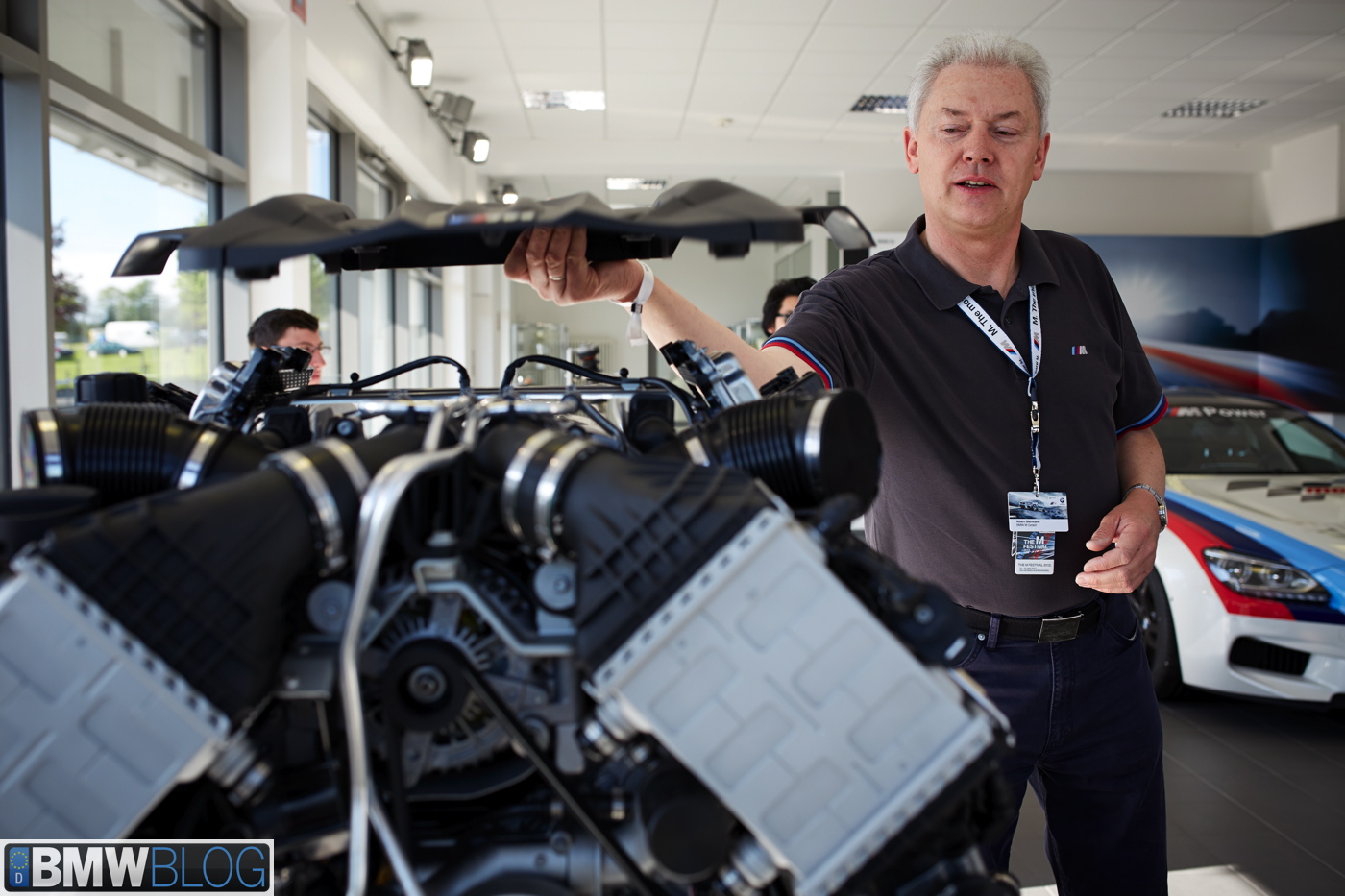

At the BMW M6 Gran Coupe U.S. launch at the Circuit of Americas, BMWBLOG had the opportunity to sit down with Albert Biermann, Vice President of Engineering, M Automobiles and BMW Individual. He’s a die-hard BMW enthusiast and true car guy.

What follows is a summary of a engineering talk he gave to the journalists about the M6 Gran Coupe’s technology and what we learned from him over dinner.

M TwinPower Turbo V8 4.4L Motor

BMW’s S63Tü 4.4 Twin Turbo V8 motor is a high revving engine and has a character very much like BMW M’s naturally aspirated engines. Many turbo motors when they run high up in the revs “run out of talent.” BMW M’s philosophy of their engines have a concept of linearity and a strong will to rev up to the limiter without slowing down.

BMW M’s S63Tü motor gets a new Competition Package that delivers more 15 horsepower this summer which is like giving a naturally aspirated motor. The way you will emotionally experience it will be as if the motor has another 200-300 rpm more. What BMW M aims for is the experience, not just numbers on paper, but more the character and the delivery of that power.

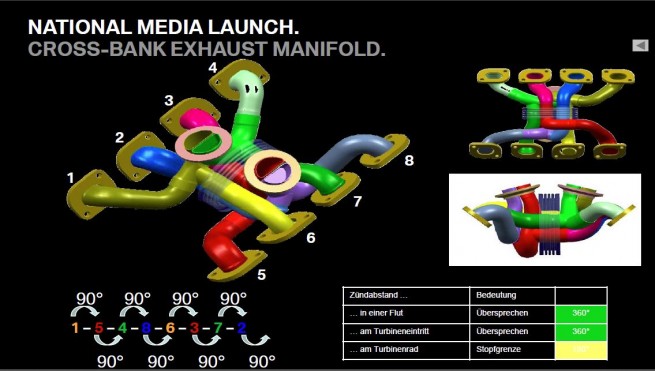

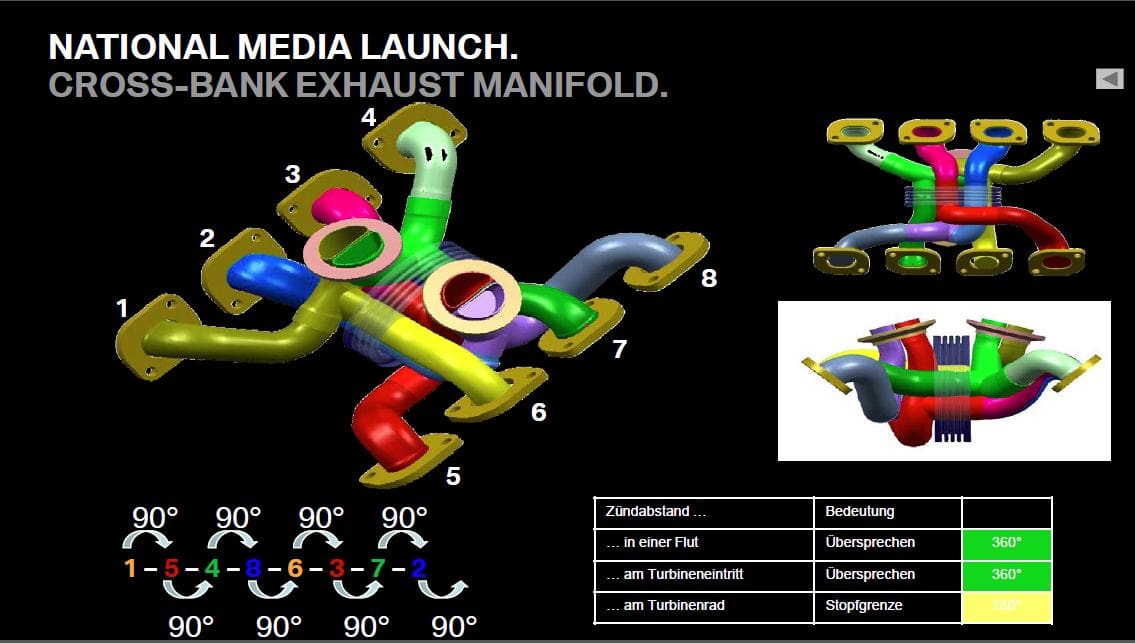

The S63Tü’s cross-bank manifold is what gives the M motor its incredibly strong heart. BMW always put two-cylinder exhaust gas into one chamber so that the combination of those two cylinders has the longest timing distance from ignition. The turbos get a constant nice airflow not the typical deletion of air fighting itself. The timing is such that the turbos are always getting exhaust gases from one bank then the next and so on.

Further, the hot V8 M motor has the turbo chargers very close to the combustion chamber providing more power and efficiency.

To shield against heat soak BMW has added tremendous cooling capacity to the M’s Twin Power Turbo V8. These include airflow over the top of the motor and more importantly cooling capacity from the radiator. Some cheap turbo chargers use fuel to cool the combustion chamber at higher RPMs and then the fuel consumption goes way up. BMW, however, uses a high precision injection system and massive intercoolers.

The charged air gets cooled with water/air cooling system. This is more expensive and a little heavier but it allows the BMW motor to keep the charged air temp down. BMW also has extra turbo pressure that it can utilize when running in a hot climate at say, the Circuit Of The Americas in the summer. This is also utilized in high altitudes. So if BMW says they have 560 hp, they have them in the Rocky Mountains at 1 mile high. So this is “real upper Bavarian Horses!“ BMW means 560hp when they say 560 hp.

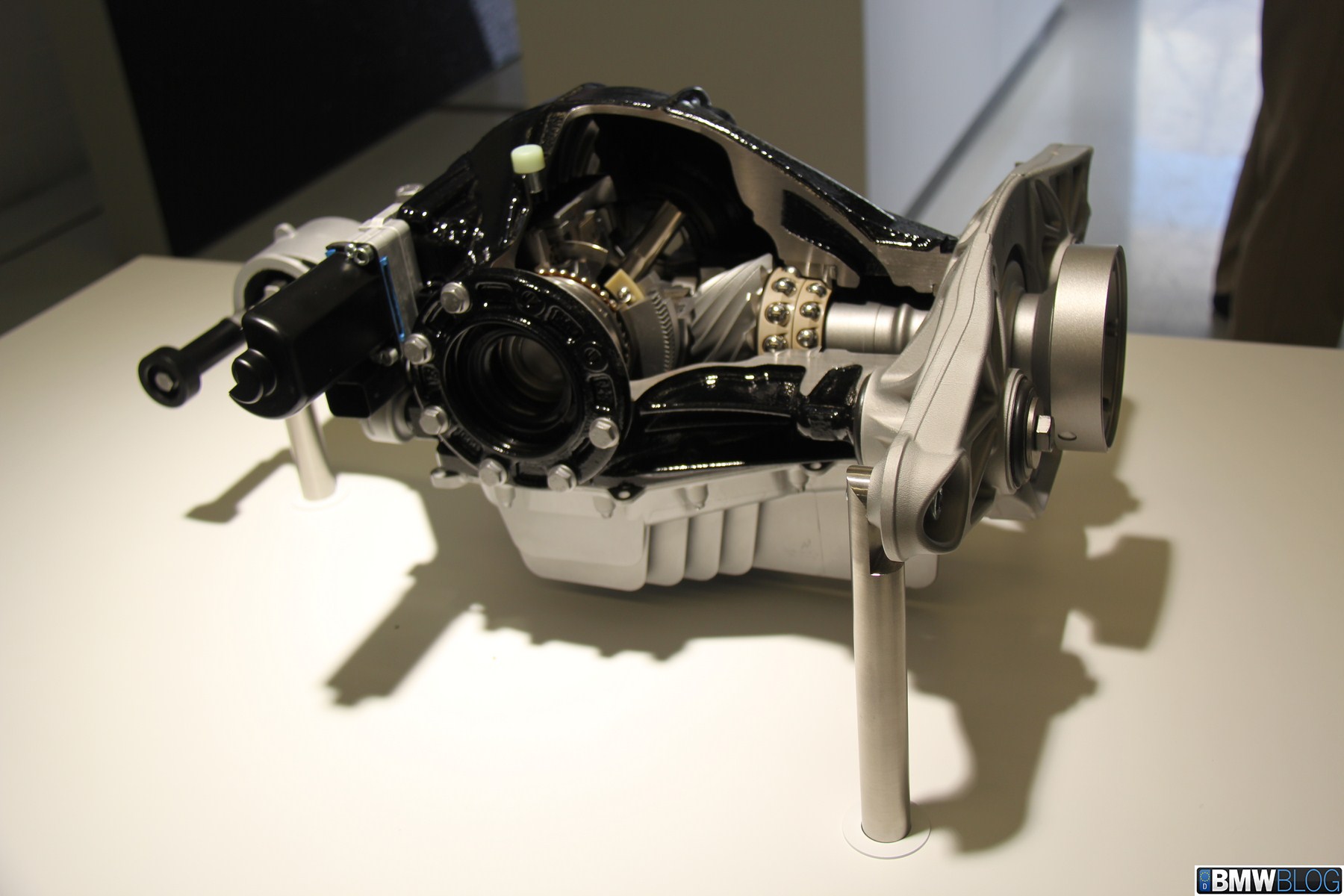

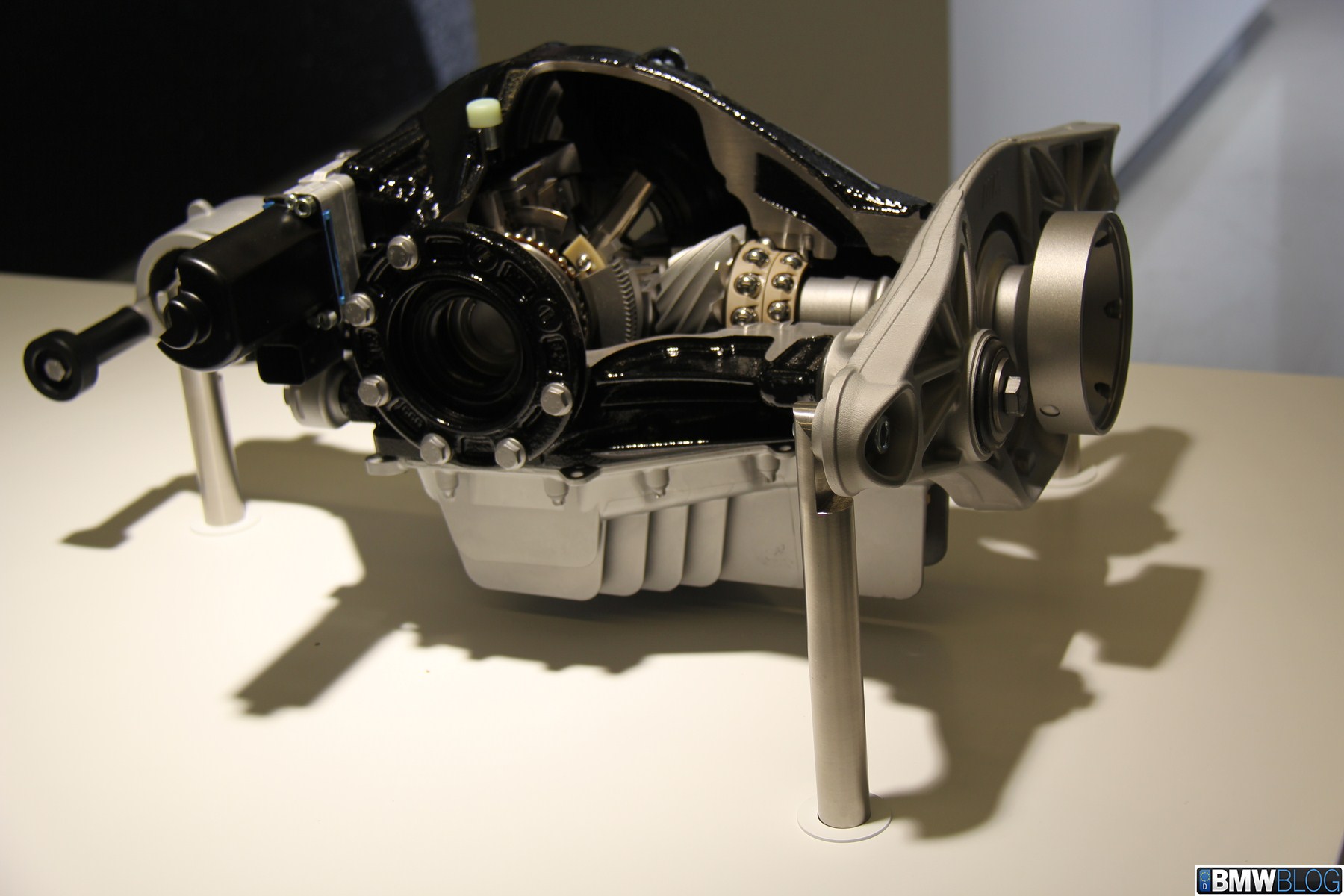

DCT and M Active Differential

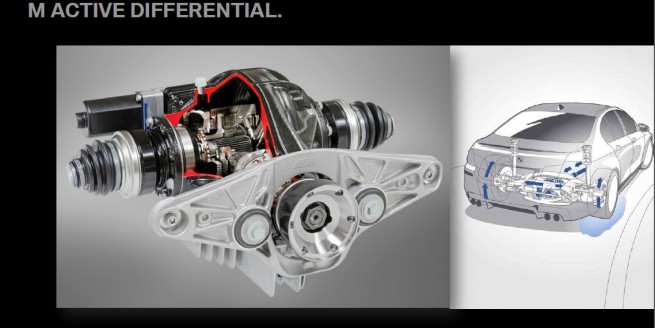

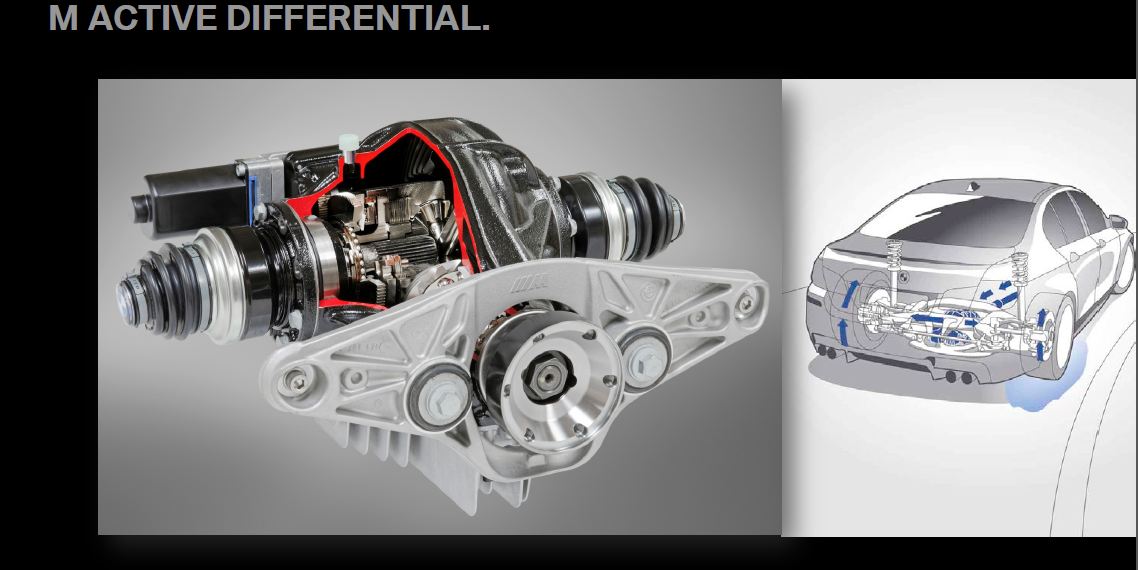

The 7-Speed M Double Clutch Transmission with Drivelogic has bigger clutches and reinforced gearing in it compared to the E92M3’s DCT. The range is also much wider in it given the enormous range of the S63Tü 4.4 liter motor than a naturally aspirated engine such as in the current M3. The rear axel area of the car has the Active M Differential.

This is how BMW M brings race car technology into day-to-day driving. The rear axel carrier has no rubber bushings just as on a race car. You do not want that movement that a rubber bushing would give. You need to have a really stout car chassis to be able to handle the forces generated. The M6 Gran Coupe has over 30,000 Nm per degree stiffness.

The BMW M cars may weigh more but they can with stand the forces generated from a seriously powerful motor transmitted via a 295 series tire. Yet, the comfort level is still there. There are three settings on the DCT for shift speed. In the DCT setting, S3 you get a jolt. Albert jokingly says the S3 mode is to honor the SMG gearbox! There is no real benefit other than the jolt. It doesn’t make you faster. He suggests S2. At the push of a

button you can set the chassis, steering, engine and DCT to your liking. When you get a combination you like, push and hold the M1 or M2 button to program your favorite combo.

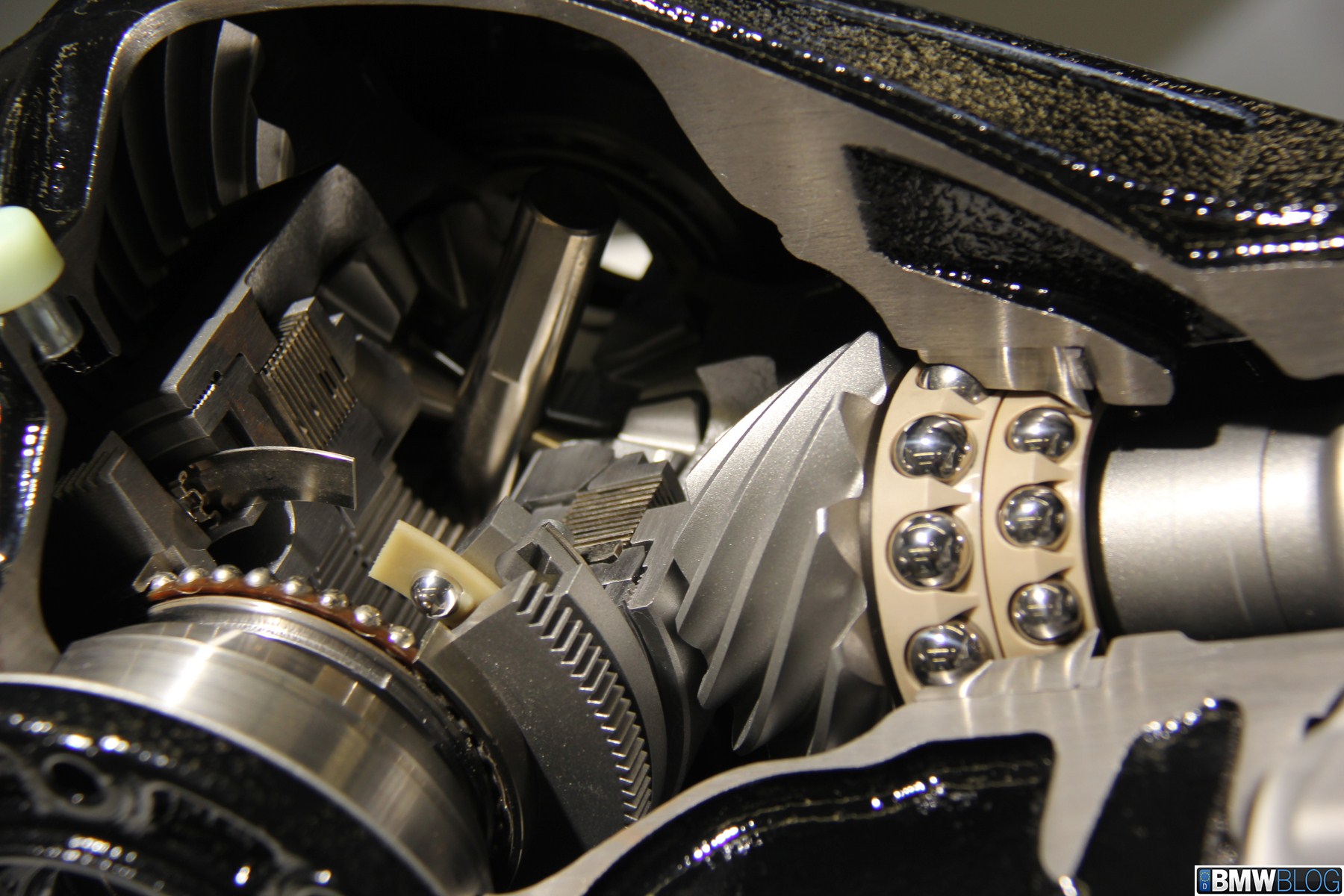

The M Active Differential can vary its lock from 0-100%. The car constantly knows every wheel speed, the yaw rate and accelerator pedal and calculates what will be needed next. The differential will set it. Full flat acceleration coming out a turn it will go to 100% lock. The opposite scenario, turning in, you want minimal torque only so you don’t get turn in understeer. In a regular limited slip, you always have some lock in and at low speed on turn in, you don’t need it. Even on a road where one side is slick and the other is not, the Active Differential can set it full open. It can go 100% to a high grip side and leave a black stripe if you want. This is rear-wheel drive at its best! BMW M wants fun, emotion and driving experience and this is the level of detail they go to to get it.

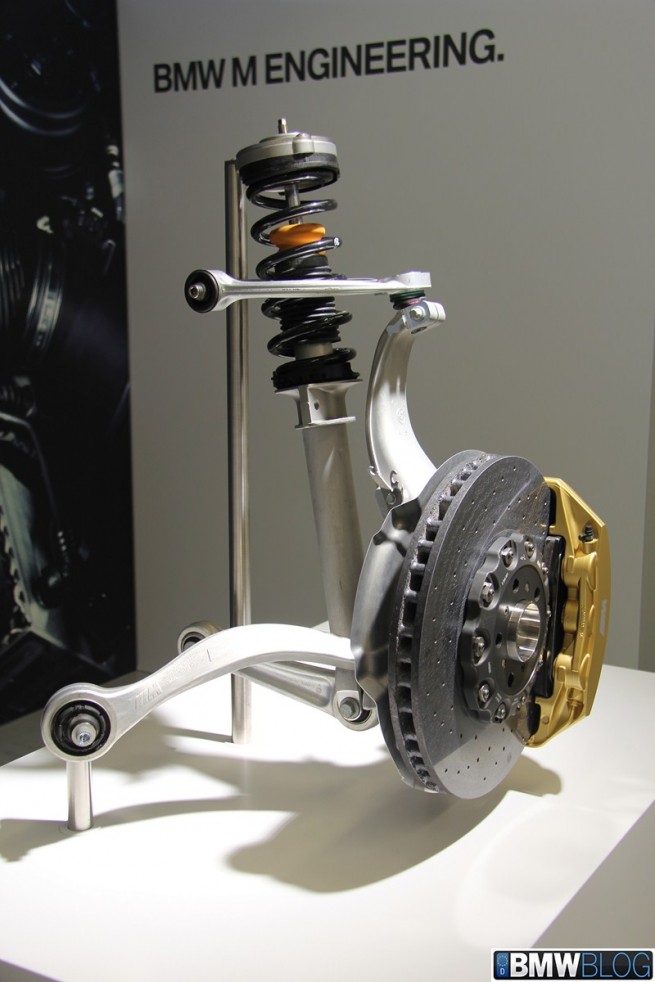

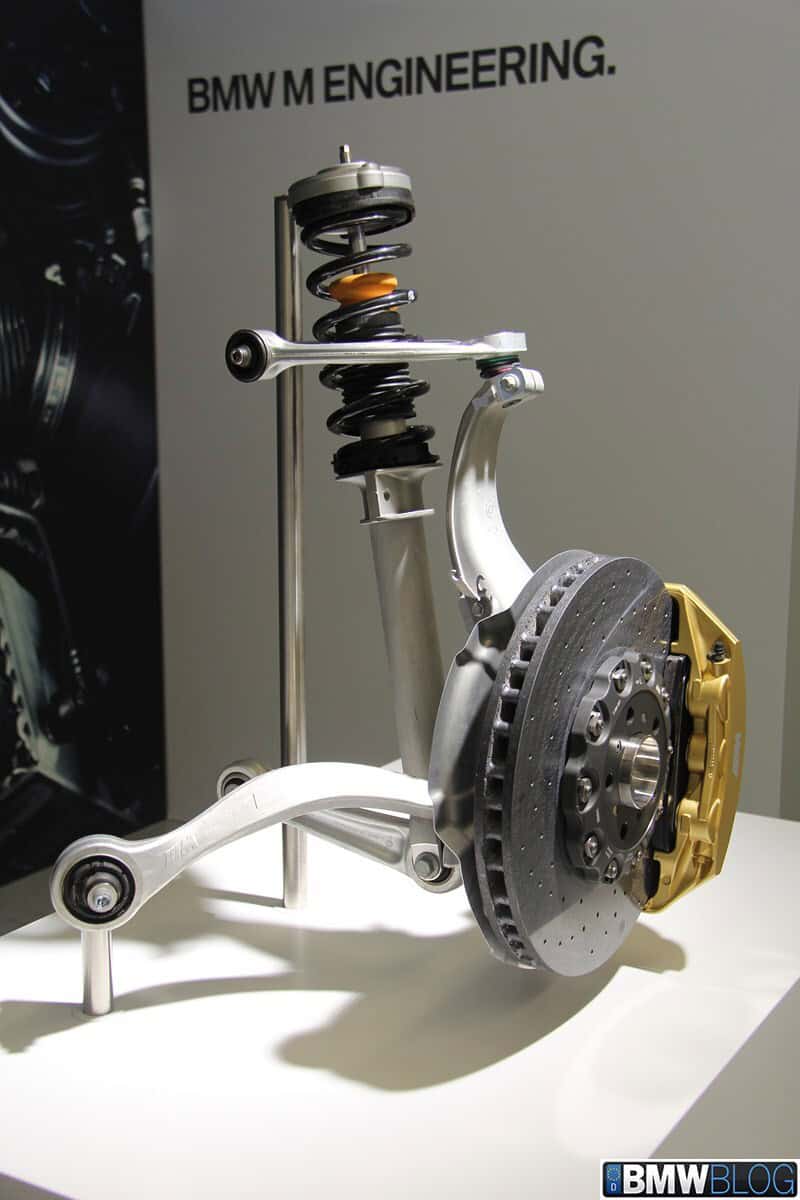

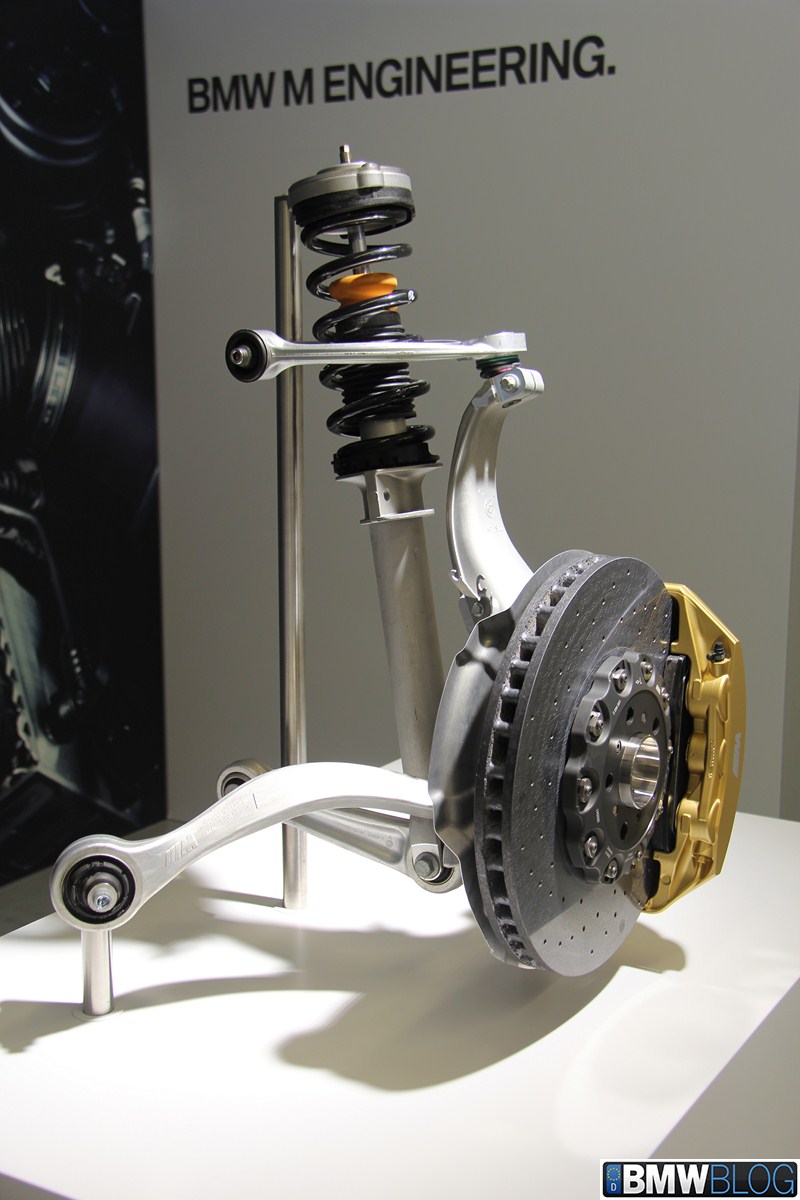

M Carbon Ceramic Brake System

The BMW M Carbon Ceramic Brake system is for those who love the German Autobahn and those who love the racetrack. Albert says he changed his strategy changed while driving at 300km/hr (186mph) on the Autobahn aboard an M6 equipped with these fantastic brakes. He used to downshift as he was braking but now with the new Carbon Ceramics he just nails the brakes. Letting the car stay in higher gear while braking instead of augmenting the car slowing with engine braking allows the engine temperatures to cool a few degrees which gives you more power when you are ready to hammer it again. A huge benefit of the Carbon Ceramic Brakes is the reduction in unsprung weight of 42 lbs, increased braking force and much better heat dissipation and fade resistance.

The brake discs of the carbon ceramics are sourced from Brembro. These are laminated just as Porsche’s Carbon Ceramics are. The brake pads for BMW’s Carbon Ceramics, however, are SGL pads. SGL, partly owned by the Quandt family, makes the carbon ceramics in a joint venture with Brembo and SGL Group. The Carbon Ceramic Brakes are last 3-4 times longer than regular steel brakes in addition to their weight savings and increased braking force. The brake fluid is the same as steel brakes. In order to determine the wear of Carbon Ceramics, you have to weigh them. That’s right, the spec is not thickness but weight!

Albert Biermannn has been with BMW for 30 years now. One of the first projects he was involved with BMW M was the E30 M3 Group A race car, the infamous Warsteiner Car. He developed the roll cage. The base E30 M3 had 12,000 newton per degree torsional stiffness and it took him almost 40 meters of high strength steel to get 23,500 Nm in the E30 M3 race car.

He absolutely loves blasting down the Autobahn at 300km/hr in the new M6 Gran Coupe outfitted with Carbon Ceramics. The M6 Gran Coupe has incredible high speed stability more so even than the M5 because of the improved aerodynamics. He also absolutely loves the M6 Gran Coupe it’s power, elegance and presence.

Here is the audio presentation by Albert Biermann:

[audio:https://dl.dropboxusercontent.com/u/3252835/M6GCtalk.mp3]