There have been drastic changes in the requirements for individual mobility concepts, in particular for conurbations. More than ever before, individual mobility is defined today in terms of sustainability. Growing traffic volume, rising energy costs and constantly increasingly stringent CO2 restrictions on vehicles in inner cities – these are the challenges of the future.

The BMW Group has recognized these challenges and is developing serial production solutions to meet the mobility needs of today and tomorrow. As an integral part of the BMW Group, BMW Motorrad is addressing issues of individual single-track mobility and future customer needs and is developing appropriate solutions in response. In this connection, BMW Motorrad has expanded its business activities with the addition of the facet “Urban Mobility”, presenting two serial production vehicles in 2011 – the maxi scooters C 600 Sport and C 650 GT.

Following the BMW Group’s sustainability strategy, BMW Motorrad aspires to consistently pursue electromobility at this early stage, especially in the urban environment. In a similar way to BMW i in the automotive division of the BMW Group, BMW Motorrad’s accelerated development of single-track mobility likewise stands for visionary vehicle concepts and mobility services – as well as inspiring design and a new premium philosophy clearly defined by sustainability across the entire value creation chain.

BMW Motorrad will thus be launching an appropriate premium product on the market in the foreseeable future. The concept vehicle E-Scooter was presented at the BMW Motorrad Innovation Day 2011 as the first development stage in this direction. Due to their limited performance and range, purely electrically powered scooters have been suitable almost solely for inner-city use with a restricted range of operation up to now. With its sustainable technological solutions, however, the concept vehicle BMW E-Scooter already shows a significantly extended range of operation. Shortly after this, the second development stage saw its premiere at the IAA in Frankfurt: the design study of an e-scooter made by BMW Motorrad – BMW Concept e. This embodies the aesthetic vision of an electrically powered scooter.

The third development stage now follows with the “C evolution”: BMW Motorrad presents the near-production prototype of an e-scooter as it might soon go on the market. Since it was conceived as a future-oriented vehicle for commuting between the urban periphery and the city centre, there were two particular requirements for its development: performance figures comparable to those of a maxi scooter with a combustion engine and a long range in realistic conditions of use.

With its deployment of five fully ridable “C evolution” scooters, BMW Motorrad has extended its experience in the field of e-mobility with single-track vehicles and continues to expand its expertise in this segment. BMW Motorrad is also making use of a number of events in Europe to further raise the profile and promote acceptance of single-track electrically powered vehicles, thereby preparing the market for such a vehicle with a view to launching a serial production model. In this pilot phase, the vehicles are being operated in real conditions of use and within areas which reflect their intended environment. The aim here is also to explore the infrastructure, such as establishing a network of e-mobility providers which might include vehicle rental companies and car-sharing firms.

The highlights at a glance:

• Innovative electric drive via drivetrain swing arm with liquid-cooled alternator, tooth belt and planetary gear.

• 11 kW continuous output (homologation according to ECE R85) and 35 kW peak output.

• 120 km/h max. speed.

• High range of up to 100 kilometres due to large battery capacity.

• High-voltage battery with high capacity (8 kWh) and innovative air cooling.

• Intelligent recuperation in coasting mode and when braking.

• Short charging times.

• Synergy effects with BMW automobiles and electrical safety

to car standards.

• Hybrid chassis with agile handling due to low centre of gravity.

• Powerful braking system with ABS.

• Lightweight Metzeler Feelgreen tyres.

• Multifunctional TFT instrument cluster and LED daytime running light.

• Innovative colour concept and design.

2. Technology and design.

Electro-performance at the level of a combustion engine.

With 11 kW continuous output (homologation according to ECE R85 to determine motor outputs) and 35 kW peak output, the “C evolution” has a powerful motor and provides a high level of riding fun. The top speed is electronically limited to 120 km/h. The scooter supremely handles motorway riding and overtaking – even with a passenger. It is also capable of effortless hill starts on steep slopes with a pillion passenger. In terms of acceleration from 0 to 60 km/h, it comfortably holds its own against current maxi scooters a capacity of 600 cc or more.

Compared to conventional combustion engines, the electric drive of the “C evolution” also offers significant advantages at low speeds in particular. Thanks to elaborate power electronics settings, the alternator offers the rider an instant, spontaneous response. There are no delays in torque build-up at all as are typical in combustion engines due to the clutch engaging and disengaging.

High range of up to 100 kilometres due to large battery capacity.

At 8 kWh, the storage capacity of the battery is extremely generous and ensures a range of up to 100 kilometres. This means that realistic zero-emissions riding in the big city and in urban environments is no problem at all. As in other areas, BMW Motorrad has been able to draw on synergy effects with BMW automobiles here. For example, the “C evolution” uses the same lithium-ion storage modules as are installed in the BMW i3. Here, developers paid particular attention to the quality and service life of the storage modules so as to ensure that the range is preserved even after many years of service life and in very cold weather.

One of the main technological challenges was optimum cooling of the high-voltage battery. On the one hand it was necessary to avoid excessively low temperatures due to the fact that the interior resistance of the cells is heavily increased as a result, thereby reducing power. On the other hand, the temperatures must not be too high since this would impair the lifetime of the cells.

While in electrically powered cars a cooling agent is normally used to cool the battery, air cooling is used in the “C evolution” in order to save space and weight. The heat of the high-voltage battery is dissipated by means of an aerodynamically optimised cooling air shaft at the centre of the battery casing through which there is a constant flow of air. To ensure optimum heat dissipation, the battery base has longitudinally arranged cooling ribs.

However, the battery casing in die-cast aluminium not only holds the cells with their special architecture but also the entire electronics unit for monitoring the cells. It also acts as a load-bearing chassis element.

The power electronics for the electric drive is installed behind the battery casing. This not only takes care of controlling the alternator within a range of 100 to 150 volts but also responds to rider commands, for example by detecting the position of the throttle grip. The system also processes information from the brake system and decides whether energy should be recuperated and how much recuperation torque is to be applied to the rear wheel if required.

Innovative electric drive via drivetrain swing arm with liquid-cooled alternator, tooth belt and planetary gear.

The “C evolution” is powered via a drivetrain swing arm. The alternator is positioned behind the battery casing and integrated in the swing arm. Due to the proximity of the alternator output shaft and the swing arm axle, the moment of inertia around the swing arm centre of rotation is minimised. This also provides optimum suspension/damper settings and a sensitive response.

The secondary drive is via a tooth belt from the alternator to the rear belt pulley on the output shaft. From here, power is transferred to the rear wheel via a planetary gear. The total gear reduction is 1:8.4, while the maximum rotational speed of the alternator is 10,000 rpm.

The alternator and power electronics are liquid-cooled.

Intelligent recuperation in coasting mode and when braking.

BMW Motorrad has conducted lengthy road tests to develop a form of recuperation which is unique in single-track vehicles and very transparent for the rider. The “C evolution” is ridden in exactly the same way as a scooter with combustion engine. The rider does not have to actively initiate energy recuperation since the vehicle does this automatically whenever possible.

For example, energy recuperation commences when the throttle grip is closed and – as in a combustion engine – the generator function of the alternator creates drag torque which depends on the degree of recuperation. The drag torque generated by the alternator is like the familiar “engine brake” that takes effect when removing the accelerator with a combustion engine.

Recuperation is also carried out during braking, converting kinetic energy to electrical energy so as to charge the battery. Here, a system of sensors is used to tap into the brake pressure on the front and rear wheel brake. When the power electronics detects that the rider is braking, the alternator builds up drag torque, thereby supporting the brake manoeuvre and recuperating energy. By regaining energy during coasting or braking, the range of the two-wheeler can be extended by 10 to 20 per cent, depending on riding style.

Short charge times and charging technology based on the car model.

The battery is charged via the integrated charging device, either at a regular household socket or a charging station. When the battery is completely flat, charging time ideally lasts less than three hours.

The car-type charging socket – currently the only one of its kind in an electrically powered two-wheel vehicle – is located behind a cover in the footwell at front left. The charge cable required is housed in a storage compartment on the right-hand side of the footwell. It is fitted with a mains plug to fit the respective national system.

The fact that the charge socket is the identical to the car standard has the advantage that the “C evolution” can be charged at charge stations throughout the USA with integrated charge cable and standardised plug, for example. This technology is not currently offered by any other electrically powered two-wheeler. Charge cables with the relevant specifications will be offered in later serial production models so that they can be charged at stations in Europe.

Synergy effects with BMW automobiles and technical safety according to car standards.

As a company of the BMW Group, BMW Motorrad is one of the very few motorcycle manufacturers to be able to draw on in-house experience and expertise in the automobile field in the development of electrically powered vehicles. The synergies available here range from the use of the same technical components through to high-voltage technology and the associated safety requirements in terms of cables, plugs, battery electronics and safety shutdown.

This also includes the insulation monitoring device, the high-voltage indicator, the high-voltage distributor and the DC-DC converter which serves to convert high voltage to low voltage so as to feed the 12-volt vehicle power system and the control units.

High-voltage safety standards established by leading automobile manufacturers (> 60 volt direct current) and functional reliability have been applied to an electrically powered two-wheel vehicle for the first time here. Development in accordance with ISO 26262 is currently unique among (electrically powered) two-wheel vehicles and ensures that all functionally relevant features are developed in accordance with standards and reflect the current state of science and technology.

Hybrid chassis with agile handling due to low centre of gravity.

Unlike existing maxi scooters with combustion engine, the “C evolution” does not have a main frame in the usual sense. The aim of chassis development for the “C evolution” was to combine the best possible directional stability at high motorway speeds with agile handling in urban traffic. Engineers also set out to make full use of the advantages provided by an extremely low centre of gravity – due to the low position of the battery. For this reason, chassis design is based on a torsionally stiff hybrid composite structure made up of a load-bearing, torsionally rigid battery case made of cast light alloy with integrated mounting for the single-sided drivetrain swing arm. Bolted onto this are the steering head support and the rear frame in steel tubing. In urban traffic in particular, the riding experience is characterised by extremely light handling and excellent slow-running properties. The weight of the vehicle is at a level comparable to maxi scooters with a combustion engine.

Wheel control as well as suspension and damping is taken care of at the front by an upside-down fork with a generous fixed fork tube diameter of 40 mm. The rear wheel suspension consists of a single-sided drivetrain swing arm. At the rear, suspension and damping are performed by a spring strut placed on the left-hand side, directly controlled and adjustable at the spring mount. The spring travel is 115 millimetres at front and rear, thereby offering a high degree of comfort.

Lightweight tyres to reduce rolling resistance.

At the front, the “C evolution” rolls on a 5-spoke light alloy die-cast wheel, size 3.5 x 15 inches, while the size of the rear wheel is 4.5 x 15 inches.

In order to reduce rolling friction and thus make the most efficient use of the electrical energy stored, the “C evolution” has lightweight tyres. These are special Metzeler Feelgreen tyres with optimised rolling resistance in the sizes 120/70 R15 at front and 160/60 R15 at rear. The tyres were developed with two clear aims in mind: environmental compatibility and high efficiency based on minimising rolling resistance, at the same time providing a higher mileage. Rolling resistance was reduced by 25 per cent as compared to the Metzeler Feelfree tyres. At the same time, the Metzeler Feelgreen tyres are very light, with reduced hysteresis response and a new tread with specially created tread grooves for optimised rolling resistance.

Powerful braking system with ABS.

At the front, a twin disc brake system with 270-millimetre diameter and

2-piston floating calipers ensures powerful, safe deceleration. At the rear there is a single disc system also with a diameter of 270 millimetres and 2-piston floating caliper. In order to achieve a stable pressure point and optimum controllability, all brake lines are steel-wrapped.

A high level of active safety is ensured by the BMW Motorrad ABS. Weighing just 700 grams and extremely small in size, the Bosch 9M dual channel ABS allows separate regulation of the two brake cycles for front and rear brakes. However, the ABS software has also been adapted so as to control the recuperation process in line with the specific requirements of the “C evolution”. As in the BMW Motorrad maxi scooters C 600 Sport and C 650 GT, the hold brake is activated automatically when the side stand is folded out.

Multifunctional instrument cluster and LED daytime running light.

The instrument panel of the “C evolution” has a large, easily legible TFT display which is conceptually based on that of the BMW i3. It has the obligatory speed display as well as offering a wealth of other information. This includes display of the battery charge state (SOC = State of Charge) and the energy balance. The latter is displayed by means of a progress bar, indicating to the rider whether energy is currently being converted into forward propulsion or being recuperated. This information helps the rider in his efforts to ride as efficiently as possible.

In addition to the familiar indicators, the instrument cluster of the “C evolution” naturally features all the status displays required by law in electrically powered vehicles. This includes warning lamps to indicate a potential insulation error or power limitation in the event of overload (see ECE R 100).

The front lighting unit encompasses headlamps with high and low beam. The “C evolution” also features a centrally located daytime running light. At the back there is a rear light in LED technology.

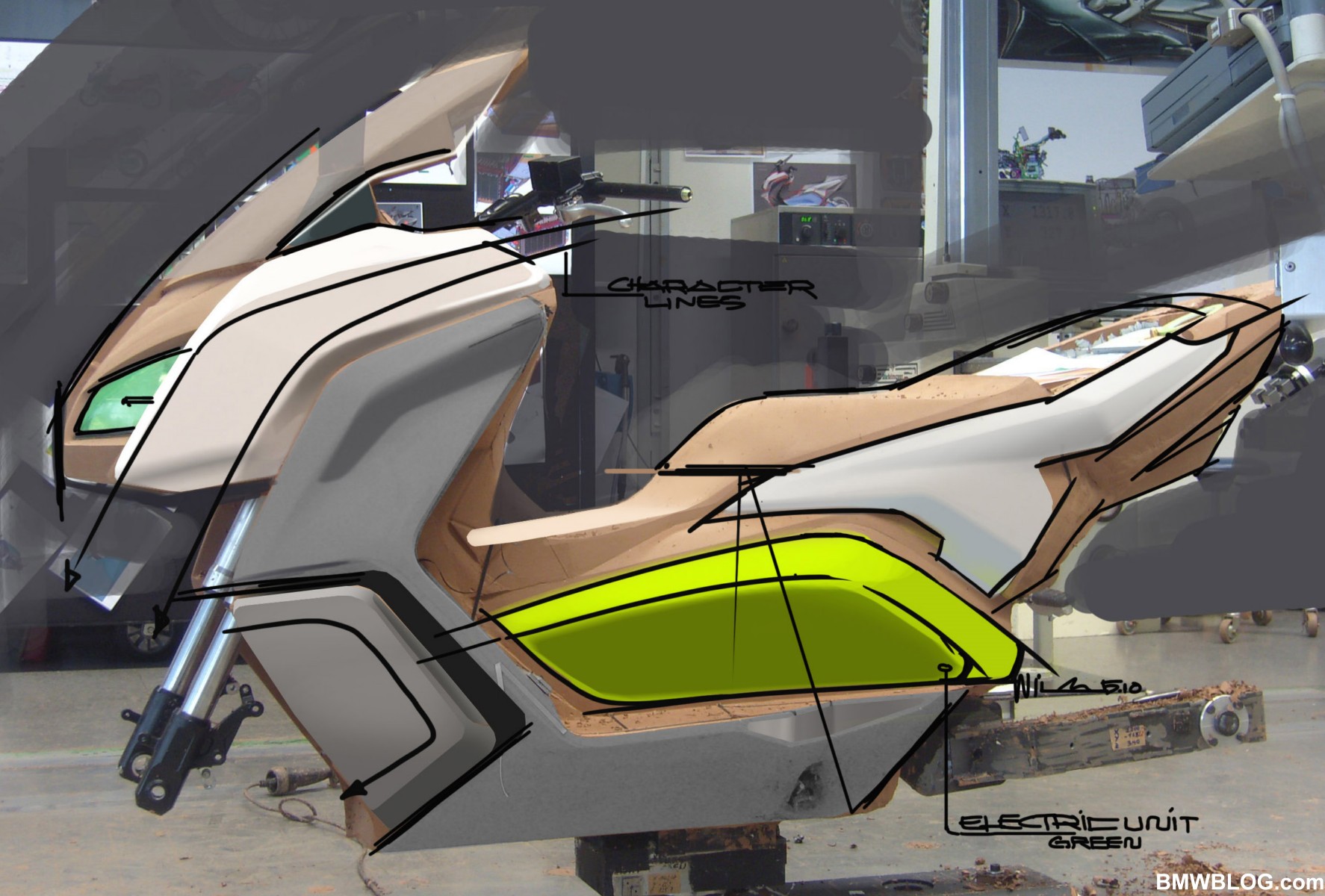

Innovative colour concept and design.

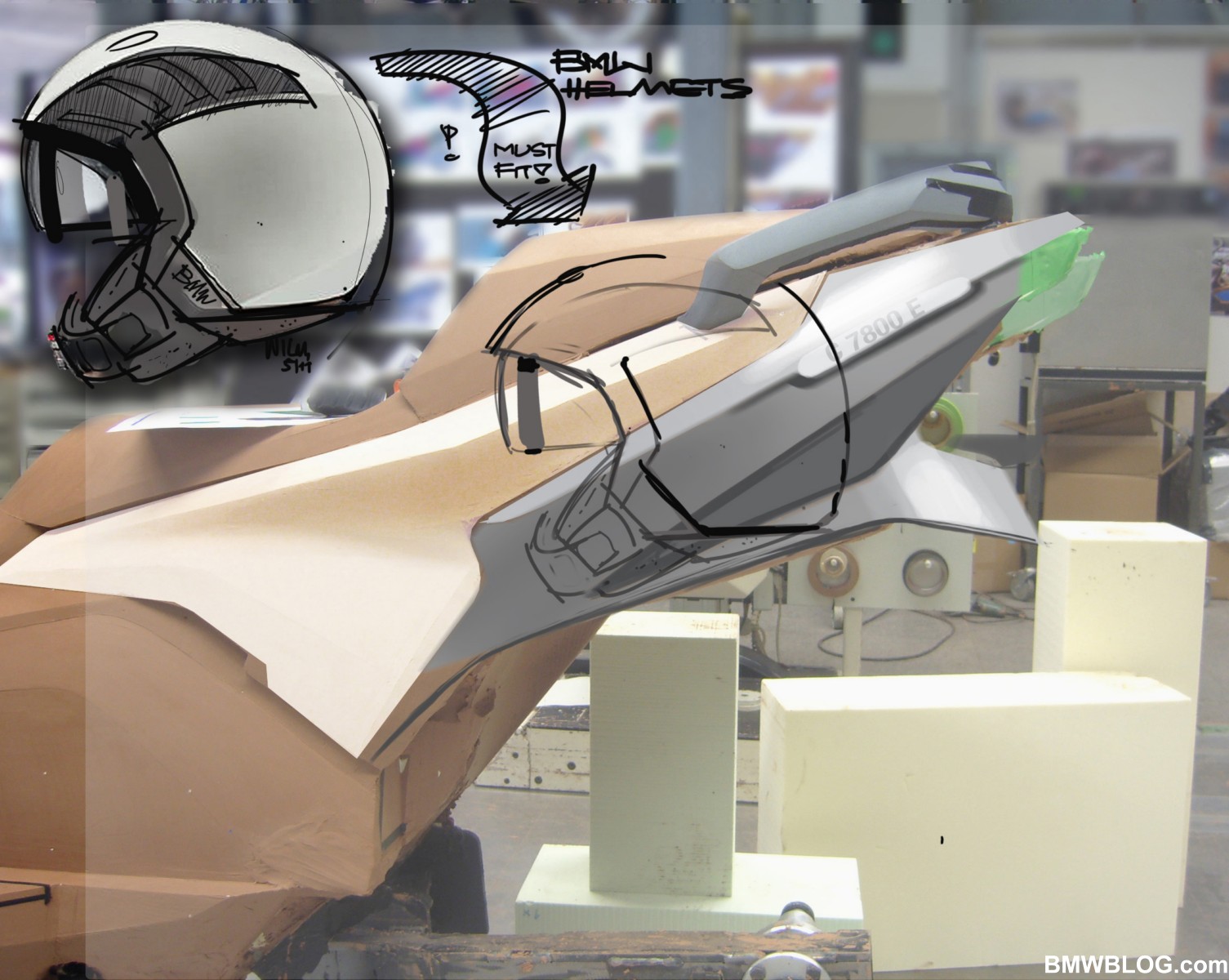

The “C evolution” draws on the innovative styling of the BMW Motorrad family, offering a thrilling, inspiring design which arouses an emotional response to the new drive technology. As in other BMW motorcycles, the so-called split face runs across the upper trim section, giving the scooter a distinctive and dynamic front view.

BMW Motorrad design style is also reflected in the styling of the twin-tipped spoiler in the front trim and in a boomerang-shaped, aerodynamically formed floating panel in the side trim. The short, sporty rear will have a helmet compartment in the serial production model and emphasises the proactive character of the “C evolution”.

The combined effect of the colour “Light white” and the highlight colour “Electric green” reflects the vehicle’s specific properties, such as maximum environmental compatibility, supreme dynamic performance and simple handling. What is more, the illuminating “e” inscription on the two battery side trim elements and motor unit bear out the technical character of an electrically powered scooter.

[Soure: BMW]